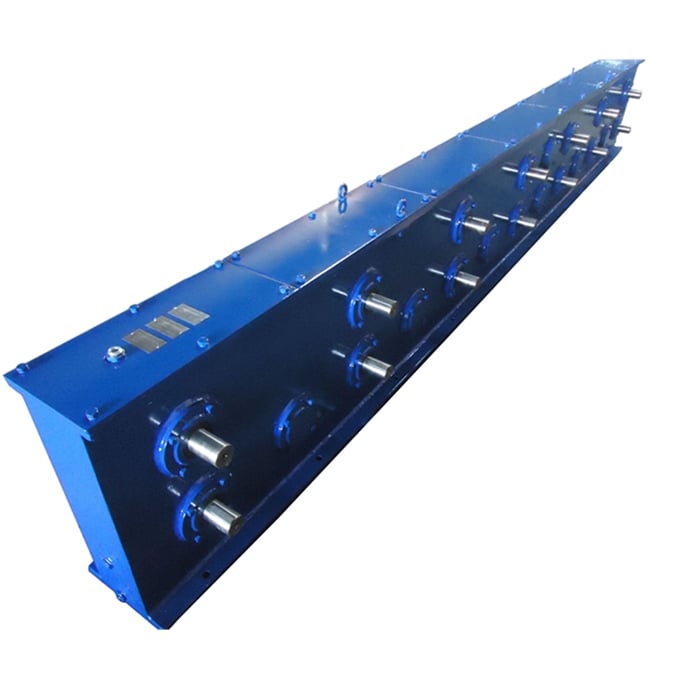

Product Description

Tractor Rotary Mowers Bevel Fertilizer Spreader Tillers Right Angle Pto Shaft Reducer Gearbox for Farm and Agricultural Machinery

Established in Nov.2002,HangZhou CHINAMFG is a professional manufacturer and supplier in supplying spare parts and accessories for agricultural machinery. In addition to the 3000 standards parts, we also offer our customers tailor-made articles or assemblies that are for special application.

HangZhou CHINAMFG focused on the development and production of gearboxes with a professional team and continue to learn advanced technology; the use of first-class equipment; high quality supply chain system, relying on these, the gearboxes get high reputation among customers at home and abroad.

These gearboxes are widely used in rotary tillers, lawn mowers, harvesters, hole diggers, pesticide sprayers, irrigation machines, fertilizer spreaders, blenders and so on. The main products are:

–Straight bevel gearbox

–Spiral bevel gearbox

–Planetary reducer

–Worm gearbox

HangZhou CHINAMFG International Trading Co.,Ltd is a modern enterprise specilizing in the development, production, sales and services of PTO shaft. We adhere to the principle of “Precise Driveline, Advocate Green”, using advanced technology and equipments to ensure all the technical standards of precise driveline. So that the transmission efficiency can be maxmized and every drop of resource of customers’ can be saved. Meanwhile, we have a customer-centric service system, providing a full range of pre-sale, sale and after-sale service. Customer satisfaction is our forever pursuit.

We follow the principle of people first, trying our best to set up a pleasant surroundings and platform of performance for each employee, so everyone can be self-consciously active to join in “Precise Driveline, Adocate Green” to embody the self-worth, enterprise value and social value.

Newnuro’s goal is: reducing customer’s purchase budget, support customers to earn more market.

Newnuro always finds solution for customers.Customer satisfaction is our ultimate goal and forever pursuit.

| Application: | Machinery, Agricultural Machinery |

|---|---|

| Function: | Distribution Power, Change Drive Torque, Change Drive Direction, Speed Changing, Speed Reduction, Speed Increase |

| Layout: | Assembled |

| Hardness: | Hardened Tooth Surface |

| Installation: | Horizontal Type |

| Step: | Single-Step |

| Samples: |

US$ 50/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Can tractor PTO shafts be customized for specific implement or machinery requirements?

Yes, tractor power take-off (PTO) shafts can be customized to meet specific implement or machinery requirements. Customization allows for the optimal integration of PTO shafts with different agricultural implements and machinery. Here’s a detailed explanation:

1. Length and Size: PTO shafts can be customized in terms of length and size to suit specific requirements. Different implements or machinery may have varying distance requirements between the tractor’s PTO output and the input shaft of the implement. Customizing the length ensures proper alignment and a secure connection. Additionally, the size of the PTO shaft, such as the diameter, can be adjusted to match the power and torque requirements of the implement.

2. Attachment Methods: PTO shafts can be customized to accommodate different attachment methods required by specific implements. The attachment method refers to how the PTO shaft connects to the implement’s input shaft. Common attachment methods include a shear pin, a quick-release collar, or a splined connection. Customization allows manufacturers to provide the appropriate attachment method based on the implement’s design and requirements.

3. Shaft Configurations: PTO shafts can have different configurations to suit specific implement or machinery designs. For example, some implements may require a straight shaft, while others may need a telescopic or sliding shaft to accommodate variable distance requirements during operation. Customizing the shaft configuration ensures a proper fit and allows for smooth operation without compromising safety.

4. Protection and Shielding: Customization of PTO shafts can include additional protection and shielding features. Agricultural tasks often involve debris and potential hazards that can damage the PTO shaft. Manufacturers can customize the shaft by adding protective guards, such as metal or polymer shields, to prevent entanglement or contact with external objects. This customization enhances safety and prolongs the lifespan of the PTO shaft.

5. Specific Industry Standards: Some industries or applications may have specific standards or regulations for PTO shafts. Manufacturers can customize PTO shafts to meet these specific industry requirements, ensuring compliance with safety standards and compatibility with machinery used in those industries.

It’s important to note that the customization of PTO shafts is typically carried out by the manufacturers or specialized suppliers. They have the expertise and knowledge to design and manufacture customized PTO shafts that meet the required specifications and standards.

In summary, tractor PTO shafts can be customized to accommodate specific implement or machinery requirements. Customization options include adjusting the length and size, adapting attachment methods, configuring the shaft design, adding protection and shielding, and meeting specific industry standards. Customized PTO shafts ensure optimal integration and performance, enhancing the overall efficiency and safety of agricultural operations.

How do manufacturers ensure the compatibility and quality of tractor PTO shafts?

Manufacturers employ several measures to ensure the compatibility and quality of tractor PTO shafts. These measures include:

1. Design and Engineering: Manufacturers invest significant effort in designing and engineering PTO shafts to meet industry standards and specifications. They consider factors such as power requirements, torque capacity, rotational speed, and attachment methods. Through extensive research and development, manufacturers aim to create PTO shafts that are compatible with a wide range of tractors and agricultural implements.

2. Material Selection: High-quality materials are crucial for the durability and performance of PTO shafts. Manufacturers carefully select materials that can withstand the demanding operating conditions of agricultural machinery. Common materials include high-strength alloy steels for shafts, precision bearings for universal joints, and durable polymers for shielding components.

3. Quality Control: Manufacturers implement stringent quality control processes to ensure that each PTO shaft meets the required standards. This involves comprehensive inspections and tests at various stages of production, including material inspection, dimensional checks, and performance testing. Quality control measures help identify and rectify any defects or deviations from the specified tolerances.

4. Compliance with Standards: Tractor PTO shafts are designed and manufactured to comply with industry standards and regulations. These standards, such as ISO 500 and ASABE S318, outline the requirements for PTO shaft dimensions, safety features, and performance characteristics. Manufacturers ensure that their PTO shafts meet or exceed these standards to ensure compatibility and safety.

5. Compatibility Testing: Manufacturers conduct compatibility testing to verify the performance and compatibility of their PTO shafts with various tractors and agricultural implements. This testing involves rigorous assessments of factors such as attachment methods, alignment, power transmission efficiency, and dynamic loads. By testing their PTO shafts with different equipment models and configurations, manufacturers can identify any compatibility issues and make necessary adjustments.

6. Technical Support and Documentation: Manufacturers provide technical support to assist customers in selecting the appropriate PTO shafts for their specific requirements. They offer documentation, including product catalogs, technical specifications, and installation guides, to help users understand the compatibility and installation procedures. Clear instructions and support materials contribute to the proper selection and installation of PTO shafts.

By employing these measures, manufacturers ensure the compatibility and quality of tractor PTO shafts. Robust design and engineering, careful material selection, stringent quality control, compliance with standards, compatibility testing, and comprehensive technical support all contribute to the reliable performance and longevity of PTO shafts in agricultural applications.

What Benefits Do Tractor PTO Shafts Offer for Various Agricultural Tasks?

Tractor power take-off (PTO) shafts offer numerous benefits for various agricultural tasks. They provide a versatile and efficient means of powering different implements used in farming operations. Here’s a detailed explanation of the benefits that tractor PTO shafts offer for various agricultural tasks:

1. Versatility:

One of the key benefits of tractor PTO shafts is their versatility. PTO shafts allow farmers to connect a wide range of implements to their tractors, including rotary mowers, tillers, balers, spreaders, and more. This versatility enables farmers to perform different tasks with a single tractor, eliminating the need for multiple specialized machines. Farmers can easily switch between implements, adapting to various agricultural activities and increasing operational efficiency.

2. Increased Efficiency:

Tractor PTO shafts significantly enhance efficiency in agricultural tasks. By utilizing a single power source (the tractor’s engine) to drive multiple implements, farmers can streamline their operations and save time. Instead of manually operating separate machines, farmers can leverage the power and speed control offered by the tractor’s PTO shaft to efficiently perform tasks such as mowing, tilling, planting, harvesting, and more. This increased efficiency allows farmers to accomplish more work in less time, leading to improved productivity.

3. Cost Savings:

The use of tractor PTO shafts can result in cost savings for farmers. By eliminating the need for dedicated engines on each implement, farmers can avoid the expense of purchasing and maintaining multiple machines. Additionally, the versatility of PTO shafts allows farmers to invest in a smaller number of implements that can be used for multiple tasks, further reducing costs. The cost savings associated with tractor PTO shafts can contribute to improved profitability and financial sustainability for farmers.

4. Flexibility:

Tractor PTO shafts offer flexibility in agricultural operations. Farmers can easily attach and detach implements as needed, depending on the specific task at hand. This flexibility allows for rapid adaptation to changing field conditions, crop types, or seasonal requirements. Farmers can quickly switch between implements, such as switching from a mower to a seeder or from a tiller to a sprayer. The ability to utilize different implements with a single tractor provides farmers with the flexibility to optimize their operations and respond to varying agricultural demands.

5. Precise Power Control:

Tractor PTO shafts provide precise power control, allowing farmers to adjust the rotational speed and torque delivered to the implement. Different agricultural tasks require specific power requirements, and the ability to adjust the PTO speed allows farmers to optimize the performance of attached implements. For instance, certain tasks may require higher rotational speed for efficient cutting or lower speed for precise soil cultivation. The ability to control power output through the PTO shaft contributes to improved accuracy and effectiveness in various agricultural operations.

6. Standardization:

Tractor PTO shafts follow standardized connection interfaces, ensuring compatibility between tractors and implements from different manufacturers. This standardization allows farmers to easily connect implements to their tractors without compatibility issues. Farmers have a wide range of implements to choose from, and the standardized PTO shaft connection ensures seamless integration and operation. Standardization simplifies equipment selection, replacement, and compatibility concerns, enhancing the convenience and effectiveness of agricultural tasks.

7. Safety Considerations:

While not a direct benefit for agricultural tasks, tractor PTO shafts incorporate safety features to protect operators and bystanders. PTO shafts are typically equipped with protective guards or shields that cover the rotating shaft, reducing the risk of accidents or entanglement. These safety features help prevent injuries and promote safe working conditions in agricultural operations.

In summary, tractor PTO shafts offer numerous benefits for various agricultural tasks. They provide versatility, increased efficiency, cost savings, flexibility, precise power control, and standardized compatibility. By leveraging the power of the tractor’s engine, PTO shafts enable farmers to efficiently power different implements, enhancing productivity and optimizing farming operations.

editor by CX 2023-09-28

China Farm Agricultural Lawn Mowers Bevel Digger Drive Replace Reducer Transmission Pto Shaft Gearbox for Fertilizer Spreader pto shaft came apart

Product Description

Farm Agricultural Lawn Mowers Bevel Digger Push Substitute Reducer Pto Shaft Gearbox for Fertilizer Spreader

Proven in Nov.2002,HangZhou CZPT is a skilled company and supplier in supplying spare elements and components for agricultural equipment. In addition to the 3000 expectations elements, we also supply our buyers tailor-created posts or assemblies that are for particular software.

HangZhou CZPT targeted on the improvement and generation of gearboxes with a expert staff and carry on to find out superior engineering the use of 1st-course products substantial top quality offer chain system, relying on these, the gearboxes get high reputation amid buyers at residence and abroad.

These gearboxes are commonly used in rotary tillers, lawn mowers, harvesters, hole diggers, pesticide sprayers, irrigation machines, fertilizer spreaders, blenders and so on. The primary products are:

–Straight bevel gearbox

–Spiral bevel gearbox

–Planetary reducer

–Worm gearbox

HangZhou CZPT International Investing Co.,Ltd is a present day enterprise specilizing in the advancement, manufacturing, product sales and services of PTO shaft. We adhere to the principle of “Specific Driveline, Advocate Environmentally friendly”, utilizing sophisticated technology and equipments to ensure all the complex requirements of precise driveline. So that the transmission performance can be maxmized and each drop of resource of customers’ can be saved. Meanwhile, we have a buyer-centric services system, supplying a total variety of pre-sale, sale and after-sale service. Client fulfillment is our without end pursuit.

We adhere to the basic principle of people very first, attempting our very best to established up a pleasurable surroundings and platform of functionality for every single staff, so everybody can be self-consciously active to join in “Precise Driveline, Adocate Inexperienced” to embody the self-really worth, organization price and social value.

Newnuro’s purpose is: lowering customer’s purchase spending budget, assistance buyers to receive more market place.

Newnuro usually finds solution for buyers.Buyer fulfillment is our ultimate objective and permanently pursuit.

|

US $45 / Piece | |

200 Pieces (Min. Order) |

###

| Application: | Machinery, Agricultural Machinery |

|---|---|

| Function: | Distribution Power, Change Drive Torque, Change Drive Direction, Speed Changing, Speed Reduction, Speed Increase |

| Hardness: | Hardened Tooth Surface |

| Installation: | Vertical Type |

| Step: | Single-Step |

| Input Speed: | 540 Rpm |

###

| Samples: |

US$ 45/Piece

1 Piece(Min.Order) |

|---|

###

| Customization: |

Available

|

|---|

|

US $45 / Piece | |

200 Pieces (Min. Order) |

###

| Application: | Machinery, Agricultural Machinery |

|---|---|

| Function: | Distribution Power, Change Drive Torque, Change Drive Direction, Speed Changing, Speed Reduction, Speed Increase |

| Hardness: | Hardened Tooth Surface |

| Installation: | Vertical Type |

| Step: | Single-Step |

| Input Speed: | 540 Rpm |

###

| Samples: |

US$ 45/Piece

1 Piece(Min.Order) |

|---|

###

| Customization: |

Available

|

|---|

Safety Precautions For a PTO Shaft

When you are working around PTOs, be sure to observe several safety precautions. These include removing the shield, keeping a safe distance from the machine, and avoiding entanglement. Entanglement is a serious injury that can even lead to death. Workers who are near the machine should always maintain a safe distance, especially if the speed of the machine is fast enough to entangle clothing. The speed of the PTO is usually 540 to 1,000 revolutions per minute, and the speed is enough to cause injury in a split second.

Safety precautions

One of the most important safety precautions for a PTO shaft is to make sure that it is properly guarded at all times. An unguarded PTO shaft can entanglement a worker, cause an injury, or even cause death. Operator awareness is key in preventing this hazard. Among other things, workers should not make repairs while the PTO is in use or wear loose or frayed clothing when working near the PTO. Likewise, they should read and follow instructions provided with their tractor and implement. Finally, they should use PTO shafts only for their intended purpose.

Another important safety precaution is to wear a protective gear such as a helmet and gloves before operating a PTO shaft. This type of equipment can be extremely dangerous because of its speed. A PTO shaft that is rotating at 540 rpm can travel two metres in less than a second. Damaged shielding is a common cause of entanglement, so it is important to check your machinery for damage before operating it.

When operating a tractor, PTOs should be kept clear of loose clothing. Loose clothing can easily catch on a rotating PTO shaft. Long hair or jewelry can also become entangled in a PTO shaft. It is also important to remember to secure the PTO shaft guard when the tractor is not in use. Also, never engage a PTO when the engine is off.

Types of pto shafts

PTO shafts are used in tractors and other equipment to secure the secondary gear in the tractor. They are available in different styles and sizes. These shafts are designed to withstand pressure, impacts, and tension. They may also include a shear pin and slip clutch. Before buying a new PTO shaft, make sure to check its measurements.

There are two types of PTO shafts available in an Agric rototiller. The first one has a slip clutch and the other has a shear pin safety device. In order to identify the type of PTO shaft used in a particular tractor, it is important to understand what it is used for.

There are two types of PTO shafts: the external and internal. The latter is used for larger machines, such as a lawnmower. The former is suitable for agricultural applications and is the preferred type for large tractors. The former is suitable for plowing, mowing, and shredding.

Transmission PTO shafts are the oldest type of PTO. They are connected to the tractor’s transmission. When a tractor is in gear, it stops the PTO shaft. However, when it’s not, it’s ineffective and can pose serious problems, such as when mowing. This type of PTO can also cause an overrun clutch to prevent the PTO shaft from working properly.

Reaction time

It’s important to know your reaction time when working around a power take-off (PTO) shaft. This part of the machine rotates at approximately 540 revolutions per minute and can pull in seven feet per second. Reaction time can be affected by age, physical condition, medications, lack of sleep, and stress. If you’re working around a PTO, be sure to remove any loose jewelry or other items that might interfere with your reaction time.

PTO accidents can be caused by several factors. The operator, the machine, and the environment all play a role. The operator’s physical and mental condition can also contribute to unsafe actions. For example, young operators may lack the knowledge and experience to recognize hazards. Older workers may also have slower reaction times, which can make it difficult to react quickly to slippery work areas.

Reaction time is measured as the time between a stimulus and the response. It does not include the time required to move the hand. Reaction time is a critical factor in sports, where athletes need to be quick to respond to the moves of their opponents. A good reaction time is necessary to score points.

A demonstration of the speed of a PTO shaft is a great tool to demonstrate how dangerous this part of a machine can be. To demonstrate the speed, use a 7-foot sash cord tied to a sliding collar universal joint. Select a 540-rpm PTO shaft, and a three-inch diameter shield. In one second, the rotating shaft makes nine revolutions and travels 7.1 feet. However, a cordless drill does not rotate at full speed and will take at least two seconds to wrap around the string.

Standardization

The standardization of PTO shafts in tractors is a major project. The EU Machinery Directive requires the protection of operators from rotating parts, such as the PTO. This is especially important when parts are accessible, as clothing can easily be wrapped around them, resulting in an accident. To prevent such accidents, manufacturers have begun to install non-rotating guards over the PTO drive shaft. These guards comply with the current EU good practice.

The European Standard EN 12965:2003+A2:2009 specifies the safety requirements for PTO drive shafts and their guards. It also specifies safe working practices for these components. The standard was approved by CEN on 16 September 2019. It is important to follow these regulations to ensure safe operation.

In the 1980s, a movement began among agricultural engineers to standardize the PTO shaft. The movement began because the different types of PTO shafts had not been interchangeable. A common example is the Deutz-Fendt shaft, which had become a standard for tractors.

As the power for PTO drives comes from the gearbox, the counter shaft acts as the PTO outlet. Standardization of PTO speeds makes it easier for manufacturers to design equipment to meet a specified speed. For example, a thresher is expected to run at a specific peripheral velocity of the threshing cylinder, which is a function of standard PTO speeds. This also allows designers to plan pulley arrangements with the standard PTO speed in mind.

Safety chains

The PTO shaft is an integral part of a tractor or implement, so it’s essential to secure it with safety chains. These chains are welded to both ends of the shaft and serve as backup connections between the tractor and trailer coupling point. There are several types of chains available, from domestic to metric, to meet your specific needs.

Because of the high speeds of PTO shafts, it’s crucial to protect these parts from being tangled. A single fall of a PTO shaft can cause serious injury or even death. In such an unfortunate situation, safety chains can prevent such injuries. PTO shafts are also extremely dangerous because the components can become hot while they are operating.

In addition to safety chains, operators must also be aware of the hazards that can occur when working near a PTO shaft. Unsafe behaviors, such as performing repairs while operating a machine, or wearing frayed clothing can lead to serious injury or death. In addition, all users should follow the instructions on the tractor or implement they’re using. It’s also essential to use a PTO shaft for its intended purpose.

In addition to safety chains, farmers should also ensure that the PTO drive shaft is securely attached to the tractor or implement. A broken or damaged PTO guard can be just as dangerous as an unprotected shaft. In addition, a poorly fitting PTO guard may provide a false sense of security. For this reason, it’s important to use protective clothing when operating a tractor or implement powered by a PTO.

Shield

The CZPT-Co universal fit PTO shaft shield is a simple and easy to use shield that has a patented lever release. The shield comes in two sizes, the smaller diameter shield is for shafts with a diameter of 1 5/16″ to 2 1/8″ and the larger diameter shield fits shafts of 2″ to 3 1/8″. Each shield is pre-installed with an assortment of bearings. The shield’s length is measured from the end of the yoke bearing groove to the other end.

If you’ve ever tried to work on a PTO shaft, you know that it can be frustrating. A PTO shaft shield is a safety device that covers the shaft and prevents it from rotating. These shields are also designed to be easy to connect and remove. The CZPT safety clip makes it easy to connect or disconnect the shield, and locks into place to prevent it from rotating with the inner driveshaft. The CZPT material used in RPM Transmissions driveline safety shields is strong and rigid.

Another improvement of this PTO shaft shield is the bracket that supports the two-piece PTO shaft and outer shield. The bracket is shown in FIG. 2 as an angled front view. FIG. 7 is a side elevation view of the bracket mounted to the machine tongue.

editor by czh 2023-01-04

China Good quality Sample Customized Transmission Differential Reducer Marine Gearbox CZPT 11/43 Crown Wheel Pinion Gear with Best Sales

Product Description

HangZhou CZPT Machinery is a professional manufacture of spiral bevel gear. The company has CNC milling machine, the GLEASON milling machine, rolling inspection machine, gear measuring center, a full set of metallographic analysis, inspection equipment and other related advanced equipment.

Our company owns gear measuring center equipped with advanced testing machines such as contourgraph, universal measuring microscope and full set netlaaographic analysis detector. According to various technical requirements and through procedures of sampling, special inspection and re-examination, multi-indexes of gears like observation, measurement and tracking can be completed. And we got IATF 16949 certificate which can prove our reliable quality certainly.

With our high quality products, high credibility and trusty cooperation, aiming to be a highly specialized gear manufacturer of high level and all-directional service,we are looking forward to your business negotiation and our promising cooperation.

Q1: Are your products standard?

A: Our model is standard, if you have specific demand, pls tell us the details.

Q2: What is you main categories?

A: Commercial Vehicles like Isuzu, Nissan, Hino, Mitsubishi,Toyota, Mazda, Suzuki etc. Agricultural Machinery and Electric Storage.

Q3: If we don’t find what we want on your website, what should we do?

A: You can contact us directly by email or WeChat/WhatsApp for the descriptions and pictures of the products you need, we will check whether we have them.

B: We develop new items every month, and some of them have not been uploaded to website in time. Or you can send us sample by express, we will develop this item for bulk purchasing.

Q4: What is your terms of payment?

A: T/T 30% as deposit, and 70% before delivery. We’ll show you the photos of the products and packages before you pay the balance.

Q5:Do you test all your goods before delivery?

Yes, we have 100% test before delivery.

| Car Fitment | Toyota |

| Speed Ratio | 11/43 |

| Type | Differential Gear |

| Material | 20CrMnTi/ 8620 |

| Hardness | HRC58-62 |

| Treatment | Carburizing,Hardening, tempering,high frequency treatment,black coating,zincing,nickelage |

| Car Fitment | Toyota |

| Speed Ratio | 11/43 |

| Type | Differential Gear |

| Material | 20CrMnTi/ 8620 |

| Hardness | HRC58-62 |

| Treatment | Carburizing,Hardening, tempering,high frequency treatment,black coating,zincing,nickelage |

Types of Splines

There are four types of splines: Involute, Parallel key, helical, and ball. Learn about their characteristics. And, if you’re not sure what they are, you can always request a quotation. These splines are commonly used for building special machinery, repair jobs, and other applications. The CZPT Manufacturing Company manufactures these shafts. It is a specialty manufacturer and we welcome your business.

Involute splines

The involute spline provides a more rigid and durable structure, and is available in a variety of diameters and spline counts. Generally, steel, carbon steel, or titanium are used as raw materials. Other materials, such as carbon fiber, may be suitable. However, titanium can be difficult to produce, so some manufacturers make splines using other constituents.

When splines are used in shafts, they prevent parts from separating during operation. These features make them an ideal choice for securing mechanical assemblies. Splines with inward-curving grooves do not have sharp corners and are therefore less likely to break or separate while they are in operation. These properties help them to withstand high-speed operations, such as braking, accelerating, and reversing.

A male spline is fitted with an externally-oriented face, and a female spline is inserted through the center. The teeth of the male spline typically have chamfered tips to provide clearance with the transition area. The radii and width of the teeth of a male spline are typically larger than those of a female spline. These specifications are specified in ANSI or DIN design manuals.

The effective tooth thickness of a spline depends on the involute profile error and the lead error. Also, the spacing of the spline teeth and keyways can affect the effective tooth thickness. Involute splines in a splined shaft are designed so that at least 25 percent of the spline teeth engage during coupling, which results in a uniform distribution of load and wear on the spline.

Parallel key splines

A parallel splined shaft has a helix of equal-sized grooves around its circumference. These grooves are generally parallel or involute. Splines minimize stress concentrations in stationary joints and allow linear and rotary motion. Splines may be cut or cold-rolled. Cold-rolled splines have more strength than cut spines and are often used in applications that require high strength, accuracy, and a smooth surface.

A parallel key splined shaft features grooves and keys that are parallel to the axis of the shaft. This design is best suited for applications where load bearing is a primary concern and a smooth motion is needed. A parallel key splined shaft can be made from alloy steels, which are iron-based alloys that may also contain chromium, nickel, molybdenum, copper, or other alloying materials.

A splined shaft can be used to transmit torque and provide anti-rotation when operating as a linear guide. These shafts have square profiles that match up with grooves in a mating piece and transmit torque and rotation. They can also be easily changed in length, and are commonly used in aerospace. Its reliability and fatigue life make it an excellent choice for many applications.

The main difference between a parallel key splined shaft and a keyed shaft is that the former offers more flexibility. They lack slots, which reduce torque-transmitting capacity. Splines offer equal load distribution along the gear teeth, which translates into a longer fatigue life for the shaft. In agricultural applications, shaft life is essential. Agricultural equipment, for example, requires the ability to function at high speeds for extended periods of time.

Involute helical splines

Involute splines are a common design for splined shafts. They are the most commonly used type of splined shaft and feature equal spacing among their teeth. The teeth of this design are also shorter than those of the parallel spline shaft, reducing stress concentration. These splines can be used to transmit power to floating or permanently fixed gears, and reduce stress concentrations in the stationary joint. Involute splines are the most common type of splined shaft, and are widely used for a variety of applications in automotive, machine tools, and more.

Involute helical spline shafts are ideal for applications involving axial motion and rotation. They allow for face coupling engagement and disengagement. This design also allows for a larger diameter than a parallel spline shaft. The result is a highly efficient gearbox. Besides being durable, splines can also be used for other applications involving torque and energy transfer.

A new statistical model can be used to determine the number of teeth that engage for a given load. These splines are characterized by a tight fit at the major diameters, thereby transferring concentricity from the shaft to the female spline. A male spline has chamfered tips for clearance with the transition area. ANSI and DIN design manuals specify the different classes of fit.

The design of involute helical splines is similar to that of gears, and their ridges or teeth are matched with the corresponding grooves in a mating piece. It enables torque and rotation to be transferred to a mate piece while maintaining alignment of the two components. Different types of splines are used in different applications. Different splines can have different levels of tooth height.

Involute ball splines

When splines are used, they allow the shaft and hub to engage evenly over the shaft’s entire circumference. Because the teeth are evenly spaced, the load that they can transfer is uniform and their position is always the same regardless of shaft length. Whether the shaft is used to transmit torque or to transmit power, splines are a great choice. They provide maximum strength and allow for linear or rotary motion.

There are three basic types of splines: helical, crown, and ball. Crown splines feature equally spaced grooves. Crown splines feature involute sides and parallel sides. Helical splines use involute teeth and are often used in small diameter shafts. Ball splines contain a ball bearing inside the splined shaft to facilitate rotary motion and minimize stress concentration in stationary joints.

The two types of splines are classified under the ANSI classes of fit. Fillet root splines have teeth that mesh along the longitudinal axis of rotation. Flat root splines have similar teeth, but are intended to optimize strength for short-term use. Both types of splines are important for ensuring the shaft aligns properly and is not misaligned.

The friction coefficient of the hub is a complex process. When the hub is off-center, the center moves in predictable but irregular motion. Moreover, when the shaft is centered, the center may oscillate between being centered and being off-center. To compensate for this, the torque must be adequate to keep the shaft in its axis during all rotation angles. While straight-sided splines provide similar centering, they have lower misalignment load factors.

Keyed shafts

Essentially, splined shafts have teeth or ridges that fit together to transfer torque. Because splines are not as tall as involute gears, they offer uniform torque transfer. Additionally, they provide the opportunity for torque and rotational changes and improve wear resistance. In addition to their durability, splined shafts are popular in the aerospace industry and provide increased reliability and fatigue life.

Keyed shafts are available in different materials, lengths, and diameters. When used in high-power drive applications, they offer higher torque and rotational speeds. The higher torque they produce helps them deliver power to the gearbox. However, they are not as durable as splined shafts, which is why the latter is usually preferred in these applications. And while they’re more expensive, they’re equally effective when it comes to torque delivery.

Parallel keyed shafts have separate profiles and ridges and are used in applications requiring accuracy and precision. Keyed shafts with rolled splines are 35% stronger than cut splines and are used where precision is essential. These splines also have a smooth finish, which can make them a good choice for precision applications. They also work well with gears and other mechanical systems that require accurate torque transfer.

Carbon steel is another material used for splined shafts. Carbon steel is known for its malleability, and its shallow carbon content helps create reliable motion. However, if you’re looking for something more durable, consider ferrous steel. This type contains metals such as nickel, chromium, and molybdenum. And it’s important to remember that carbon steel is not the only material to consider.

in Tainan China, Taiwan Province of China sales price shop near me near me shop factory supplier 90 Degree RV Series Worm Gearbox Speed Reducer manufacturer best Cost Custom Cheap wholesaler

we have acquired the have confidence in of buyers worldwide. EPG has set up a full established of good quality administration method which is provided with superior inspection and take a look at products. In 2008, it was awarded with “Countrywide Export Commodity Inspection-free Business”. ninety degree RV sequence worm EPTT velocity EPTT

1. Item Features

Productive and risk-free operating.

Compact composition and tiny volume conserve mounting place.

EPT load capability and overload capabilities give steady EPTT with reduced vibration and lower noise.

Minor gap construction of EPTT makes this EPTT upkeep free and stops lubricant from leaking.

Numerous linking constructions for EPTT input and torque output permits for various mounting methods.

Reduced noise and stably running, to adapt EPTT phrase operate condition in horrible atmosphere.

LigEPTT weigEPTT and substantial mechanical energy.

EPT mounting, shaft mounting and flange mounting.

two. RV series are broadly utilised, it is an excellent decision for present day EPTT products to recognize EPTT and control at large speed reducing ratio.

| Input EPTT | .06-seven.5kW |

| Ratio | 5-100 |

| Output Torque | .06-1179N. m |

three.Purposes

HangEPT XG EPTT EPTT EPTT are commonly used in :

Ceramic Market

Glass Market

Foods Business

EPTlurgy Market

Beer amp Drink Sector

EPT and dyeing Industry

EPT Industry

Warehouse Logoistics Sector

EPT operating EPTTry

environmental defense equipment Business

Leather Sector

Pharmacy Business

4.Our Solutions

four.one.We give 12 months Guarantee.

four.2. We have thousands of EPTT EPTTs. From Enter EPTT .06KW to 200KW, Ratio one.3-289.74, Output velocity -1095rpm and Output torque 1.four-62800Nm…They can fulfill your all various requirements for diverse EPTT.

four.3. We give E-catalog or Paper catalog,so you can decide on the design simply according to your needs

4.4.You are welcome to visit our factory to verify our merchandise,we can assist you to guide the hotel or ticket

5.EPTT Details

five.1.Our EPTT:

The Predecessor for ZheJiang EPT EPTT,Ltd (initially called HangEPT XiHu (West EPT) Dis.ngguang EPTT EPTTry EPTT,Ltd) Point out-owned army mould EPTTrpriese which estabEPTTd in 1965.

EPT is located in HangEPT,EPTT and the manufacturing unit handles an area of about 25000 sq. meters.

Generation Ability:much more than fifty percent a million sets of velocity EPTT for each 12 months.

5.two.Our People:

The organization has a strong technical drive. It has a lot more than 400 personnel at present, incXiHu (West EPT) Dis.Hu (West EPT) Dis. a lot more than 40 engineering technicians and 10 professionals and senior engineers enEPTTing EPTT allowances of the State Council.

5.three. Our Certificates:

Handed quot ISO 9001 International EPTT Technique Certificate quot, quotInternational EPTT Credit history AAA Ceritifacte quot , quot Swiss SGS Certification quot, Legendary Brand name in EPTT EPTT Market quot, quotFamous Brand of ZheJiang Province quot, quotNon-public Scientific and EPTnological EPTTrprise in ZheJiang Province quot, quotNational EPT and EPTT-tech EPTTrprise quot, quotTOP 50 in EPTT EPT Business quot quot2011 HangEPT EPT and EPTnological R ampD CEPTTr quot and so on.

six. FAQ

Q:Are you a investing organization or company?

A: The predecessor of HangEPT XG-EPTT EPTTry EPTT, Ltd is Condition-owned XiHu (West EPT) Dis.ngguanggong Mold Factory, a point out-owned armed forces EPTT EPTTrprise estabEPTTd in 1965. It finished reform in 2002. Because reform, EPT has deveXiHu (West EPT) Dis.Hu (West EPT) Dis.ed swiftly. It took the guide in passing ISO9001 Intercontinental EPTT System Certificate and Global EPTT Credit AAA Certificate in 2004, and Swiss SGS Certification in 2009. It has received such titles as quotIconic Manufacturer in EPTT EPTT Sector quot, quotFamous Brand of ZheJiang Province quot, quotNon-community Scientific and EPTnological EPTTrprise in ZheJiang Province quot, quotNational EPT and EPTT-tech EPTTrprise quot, and quotTope fifty in EPTT EPT Industry quot successively

Q:Where do you base?

A: We are in HangEPT,ZheJiang ,EPTT. We have two factories,EPTT manufacturing facility is in XiHu (West EPT) Dis.hu (West EPT) Dis. district,HangEPT,EPTT and the old 1 is in CHangEPT District,HangEPT,EPTT.

Q:What kinds of EPTT can you make for us?

A:Main merchandise of our organization: JWB-X collection mechanical repeatedly variable EPTT, RV series worm EPT EPTT, B/JXJ cycloidal pin EPT velocity EPTT, NCJ collection EPT EPTT, and R, S, K, and F collection helical-tooth EPTT, a lot more than one particular hundred designs and thousands of technical specs.

Q:What are the application of the EPTT?

A:EPT are extensively used in ceramic, EPT, food, metallurgy, beer amp drink, printing and dyeing, textile, petrochemical engineering, warehouse EPT, wood-functioning EPTT, environmental security tools, printing and EPTT, pharmacy, and leather. EPT are sold in some nations around the world and areas, these kinds of as Europe, The us, and SouthEPT Asia, and it possesses dozens of distributors and right after-sale support agents.

Q:What is the substance you use?

A: EPTT case ( For the RV sequence worm EPTT,product RV030-a hundred and five)

Solid iron(For the RV collection worm EPTT, product RV110-150, For the NCJ /F/R/S/K collection helical EPT EPTT)

in Indianapolis United States sales price shop near me near me shop factory supplier F Series Parallel Helical Double Input Shaft Gearbox Speed Reducer Gear Box manufacturer best Cost Custom Cheap wholesaler

Because of to our sincerity in providing best support to our clients, knowing of your needs and overriding feeling of responsibility towards filling purchasing requirements, With numerous years’ expertise in this line, we will be trustworthy by our rewards in aggressive cost, a single-time supply, prompt response, on-hand engineering assistance and great soon after-product sales solutions.Furthermore, all our production techniques are in compliance with ISO9001 requirements. In 2000, EPG took the lead in getting ISO14001 environment management certificate and thereafter handed the inspection of clean manufacturing and recycling economy, profitable the title of “Zhejiang Environmentally friendly Enterprise”. Solution Description:

EPTT Collection EPT motor is the EPT products with intercontinental EPTd degree.incXiHu (West EPT) Dis.Hu (West EPT) Dis. R collection EPTcal EPTed motor, F collection PXiHu (West EPT) Dis.Hu (West EPT) Dis.lel shaft-EPTcal EPTed motor, K collection EPTcal-Beval EPTed motor,S series EPTcal-Worm.

EPTT sequence items follow EPT the philosophy of modularization and optimization, undertake finite component investigation technique and EPT

lower sound EPT in creating EPT ,to insure EPTd layout.The classi fication of ratio is so acurate that.

Our corpotation also supplies other solution choices this kind of as blended EPTed motor,shrink disk,spline hollow shaft, B14 flange,please consult our business for additional data.

| EPT materials | Cast iron/Ductile iron |

| EPT hardness | HBS190-240 |

| EPT material | 20CrMnTi alloy steel |

| Surface hardness of EPTs | EPTC58 deg~62 deg |

| EPT core hardness | EPTC33~forty |

| Input / Output shaft material | 42CrMo alloy metal |

| Enter / Output shaft hardness | EPTC25~thirty |

| Machining precision of EPTs | exact grinding, 6~5 Quality |

| Lubricating oil | GB L-CKC220-460, Shell Omala220-460 |

| Heat treatment | tempering, cementiting, quenching, and many others. |

| Effectiveness | ninety four%~ninety six% (is dependent on the EPTT stage) |

| Sound (MAX) | sixty~68dB |

| Temp. rise (MAX) | forty degC |

| Temp. rise (Oil)(MAX) | fifty degC |

| Vibration | le20 microm |

| Backlash | le20Arcmin |

| Model of bearings | EPTT prime model bearing, EPTB/LYC/ZWZ/C ampU. Or other manufacturers requested, SKF, NSK. |

| Brand name of oil seal | NAK — EPTTiwan or other brands asked for |

EPTcal speed EPTT far more specifics:

Our factory and in inventory :

Software spot:

Plywood EPTT and Global shipping and delivery :

FAQ

Q1: Are you trading firm or manufacturer ?

A: We are a manufacturer in EPTTngsu EPTT.welcome to our factory to have a visit.

Q2: How we decide on types and technical specs?

A:You can e-mail us the series title amp code (for illustration: WJ series worm EPTT) as properly as necessity details, this sort of as motor EPTT, output speed or ratio, service element or your software…as significantly data as attainable. If you can source some photos or drawings, it is EPT.

Q3: How is your price? Can you supply any price cut?

A: Within 12 hours.

This autumn: How EPTT ought to I wait for the suggestions soon after I send out the enquiry?

Semi-EPTT PET Bottle Blowing EPTT Bottle Generating EPTT Bottle EPTing EPTT

PET Bottle Making EPTT is suited for making PET plastic containers and bottles in all designs.

It is widely employed to produce the carbonated bottle, EPTral water, pesticide bottle oil bottle cosmetics, vast-mouth bottle and sizzling fill bottle and many others.

EPTTrage bottle, cosmetic bottle, medicine bottle, jar and so forth.

Lorem Ipsum is just dummy textual content of the printing and typesetting business. Lorem Ipsum has been the industry’s stXiHu (West EPT) Dis.Hu (West EPT) Dis.rd dummy textual content at any time since the 1500s, when an mysterious printer took a galley of type and scrambled it to make a kind specimen e-book.

Q5: What is your item guarantee time period?

A:We supply a single calendar year guarantee since the vessel departure day still left EPTT.

Q6: What EPTT are your EPTTes currently being utilized?

A:Our EPTTes are commonly utilized to metallurgical tools, mining tools, EPTT products, foodstuff EPTTry, EPTT products, tobacco tools and so on.

If you are intrigued, could you please notify me your contact data? I can send you the parameters and information of this EPT box for your reference.

China manufacturer & factory supplier for SMR in Lusaka Zambia shaft moutned pulley speed reducer power transmission 1450 rpm gearbox china gearbox gears transmission With high quality best price & service

industrial factors which includes roller chains. Roller chains are obtainable in common, nickel plated & stainless steel materials in pitch dia. ranging from 1/4 in. to 3 in. Kinds contain leaf chains in lacing configurations ranging from 2 x 2 to 8 x 8. Leaf chains are available in pitch sizes ranging from 1/2 in. to 2 in., pin dia. ranging from .156 in. to .687 in. & tensile strengths ranging from 4,000 lbs. to 156,000 lbs. Apps include agricultural, conveyors, drilling, electronics assembly, meals processing, fork elevate vehicles, hoists, packaging & textile machinery.If you need to have any information or samples, make sure you speak to uIn order to uncover a ideal gearbox for your application from the general segment, our online SIZING ASSISTANT layout instrument is ideal: primarily based on your application info or the desired motor, a ideal gearbox can be selected from our portfolio and geometry adjustment done in a couple of seconds. On desire, we can also ship you a request for quotation directly on the internet.s and you will have our quickly reply.

Overview

Swift Specifics

- Relevant Industries:

-

Building Content Shops

- Gearing Arrangement:

-

Helical

- Output Torque:

-

256-7449N.m

- Enter Velocity:

-

1400rpm

- Output Velocity:

-

a hundred~400RPM

- Location of Origin:Zhejiang, China

- Brand Identify:

-

OEM

- Coloration:

-

Blue / Gray / Consumer prerequisite

Supply Ability

- Offer Potential:

- 2000 Established/Sets for every Thirty day period

Packaging & Supply

- Packaging Particulars

- Picket situation per laptop + many pcs in large picket case

- Port

- Shanghai/Ningbo port

-

Guide Time

: -

Amount(Boxes) one – 1 >1 Est. Time(days) 30 To be negotiated

On the web Customization

EPG manufacturer rotocultivator ploughshares in T. line had been chosen as the Nationwide Rotary Tillage Equipment Industry “Best Brand name Goods” in 2007 by Rotocultivator Department of China Agricultural Machinery Market Affiliation.

SMRSlip clutch type on the rotary tiller, yet again slight oozing of grease on the UJ, do not grease the clutch these run dry and ought to be “slipped” at minimum when a calendar year to avert rusting jointly shaft moutned pulley pace reducer power transmission 1450 rpm gearbox china gearbox gears transmission

Conveyor & Material Managing

Mining & Quarry

Characteristic

1) All gears are heat handled and set to obtain lower noise and higher output

two) Mounting proportions are interchangeable with Fenner

SMR Product No. | Output Shaft Bore [mm] | Ratio(i) | |

Regular | Alternative | ||

B | Φ30 | Φ40 | 5:1 thirteen:1 20:1 |

C | Φ40 | Φ50 | |

D | Φ50 | Φ55 | |

E | Φ55 | Φ65 | |

F | Φ65 | Φ75 | |

G | Φ75 | Φ85 | |

H | Φ85 | Φ100 | |

J | Φ100 | Φ120 | |

Q1: What data should I tell you to affirm the solution?

A: Product/Size, Transmission Ratio, Shaft directions & Buy quantity.

Q2: What can i do if I never know which a single I want?

A: Don’t fear, Send as considerably information as you can, our crew will help you uncover the proper one you are seeking for.

Q3:What is your product warranty period of time?

A:We offer one calendar year guarantee given that the vessel departure date left China.

If you have yet another query, pls really feel totally free to contact us as below:

Best Custom made in China – replacement parts – PTO shaft manufacturer & factory Planetary 2004 bmw x3 rear drive shaft Reducer Gearbox with ce certificate top quality low price

We – EPG Team the largest agricultural gearbox and pto factory in China with 5 diverse branches. For far more information: Mobile/whatsapp/telegram/Kakao us at: 0086-13083988828

repairing bent pto shaft We pto coupler restore warmly 2006 bmw x3 entrance generate shaft welcome subaru forester travel shaft the pto driveline shield pals pto shaft shapes from rotavator pto shaft makers in india all jeep wj driveshaft the new holland pto shaft world! tractor pto adaptors EPG manufacturer rotocultivator ploughshares in T. line were chosen as the Nationwide Rotary Tillage Equipment Market “Perfect Manufacturer Products” in 2007 by Rotocultivator Branch of China Agricultural Equipment Industry Affiliation. Our planetary reducer gearbox have many items for your deciding on and we can create as for every your drawing or sample to satisfy your EPT ask for

Planetary Gearboxes have been designed for different transmission&interval The electricity is transmitted from the motor to solar gearboxes&interval The solar gearbox drives a few Planetary Gearboxes&comma which are contained inside of an inside toothed ring gearbox&period of time The Planetary Gearboxes are mounted on the planetary carrier&period The planetary carrier is element output shaft&period So when the sunlight gearbox rotates&comma it drives the three Planetary Gearboxes inside of the ring gearboxes&interval As Planetary Gearbox rotate with carries and routinely the optimum torque and stiffness for a offered envelope&time period The other signific EPT positive aspects are easy and efficient lubrication and a balanced program at high speeds&time period The well balanced planetary kinematics and the related load sharing make the planetary-sort gearbox really ideal for servo purposes&interval Modular concept&comma allows us to set up quick shipping time for gearboxes with a continually high stHangZhourd of quality as per your apps of reducer for motors&comma Enable our crew of engineers function for you&time period

See the below characteristics&colon

Output torque Range&colon one thousand to 450000 Nm

Transmissible Mechanical Energy&colon Up to 450 kW

Gear Ratios&colon 3 to 9000

Gear Device Variations&colon In line

Proper angle &lparwith a spiral bevel gear established&rpar

Output Configuration&colon Foot and flange mounted

Output shaft&colon Solid with important&comma spline&comma spline hollow

Hollow with shrink disc

Input Configurations

Flanged axial piston hydraulic motors

Hydraulic orbit motors

IEC and Nema motor adaptors

Solid input shaft

Hydraulic Brake&colon Hydraulically launched parking brake on request

Electric powered Brake&colon DC and AC kind

You are welcome to send us detail enquiry by e-mail or fax&interval

We can also source Gearbox&comma planetary gearbox&comma worm gearbox&comma flender gearbox&comma maritime gearbox&comma comer gearbox&comma reduction gearbox&comma transmission gearbox&comma sew gearbox&comma mower gearbox&comma rotary cutter gearbox&comma little transmission gearbox&comma gearbox for conveyor&comma agricultural gearbox&comma bevel gearbox&comma helical gearbox&comma swing gearbox&comma variable velocity gearbox&comma differential gearbox&comma small planetary gearbox&comma reducer gearbox&comma tiller gearbox&comma pto gearbox&comma gearbox reducer&comma hollow shaft gearbox&comma pace reduction gearbox&comma industrial gearbox&comma planetary reduction gearbox&comma lawn mower gearbox&comma rotary tiller gearbox&comma gearbox transmission&comma worm reduction gearbox&comma aluminum gearbox&comma forklift gearbox&comma nmrv 075 worm gearbox&comma nmrv030 worm gearbox&comma shaft mounted gearbox&comma nmrv 050 worm gearbox&comma gearbox for agricultural equipment&comma electrical power tiller gearbox&comma handbook worm gearbox&comma spiral bevel gearbox&comma nmrv gearbox&comma worm wheel gearbox&comma lessen velocity gearbox&comma industrial transmission gearbox&comma worm reducer gearbox&comma gearbox rpm reducer&comma helical gearbox reducer&comma wheel planetary gearbox&comma nmrv040 worm gearbox&comma worm gearbox reducer&comma nmrv worm gearbox&comma aluminium worm gearbox&comma gearbox reduction&comma rv series worm gearbox&comma worm speed gearbox&comma nmrv050 worm gearbox&comma equipment reducer&comma worm equipment reducer&comma helical equipment reducer&comma gear pace reducer&comma worm gear velocity reducer&comma shaft mounted equipment reducer&comma planetary gear reducer&comma helical gear pace reducer&comma worm equipment wheel reducer&comma velocity gear reducer&comma bevel gear reducer&comma planetary equipment pace reducer&comma spur gear reducer&comma aluminum worm equipment decrease&comma nmrv worm gear reducers&comma helical-worm equipment reducer&comma helical bevel gear reducers&comma higher speed equipment reducer&comma equipment pace reducers&comma industrial equipment reducer&comma high torque gear reducers

China manufacturer & factory supplier for X B in Tiruchirappalli India cyclo series vertical gearbox with motor gear reducer parallel shaft vertical parallel shaft gear reducer fa lk gear reducer With high quality best price & service

industrial factors which includes roller chains. Roller chains are offered in regular, nickel plated & stainless steel components in pitch dia. ranging from 1/4 in. to 3 in. Kinds include leaf chains in lacing configurations ranging from 2 x 2 to 8 x 8. Leaf chains are obtainable in pitch sizes ranging from 1/2 in. to 2 in., pin dia. ranging from .156 in. to .687 in. & tensilOnce the PTO has started to energy the attachment, steadily boost the throttle right up until you attain the working velocity. The normal managing RPM (revolutions per minute) for a tractor mounted PTO is 540 RPM, although there are tractor designs that rev higher. Constantly refer to your certain tractor model for instructions prior to first-time use.e strengths ranging from 4,000 lbs. to 156,000 lbs. Programs include agricultural, conveyors, drilling, electronics assembly, food processing, fork elevate vehicles, hoists, packaging & textile equipment.The group has taken portion in the producing and revising of ISO/TC100 international chain regular several many years in good results and hosted the 16th ISO/TC100 Intercontinental annual assembly in 2004.

Overview

Rapid Details

- Applicable Industries:

-

Production Plant, Machinery Repair Shops, Foods & Beverage Manufacturing facility, Farms

- Place of Origin:Zhejiang, China

- Manufacturer Title:

-

OEM

Equipment-reducer inefficiency converts electrical power to heat. AGMA ( American Equipment Makers Assn.) tips for worm-equipment, helical, and other sorts of reducers limit the optimum allowable operating temperature to 100°F earlier mentioned ambient, not to exceed 200°F. To keep in these suggestions, worm-equipment reducers must be noticeably greater than equivalent-rated helical reducers (to dissipate more warmth) or rely on auxiliary cooling devices.

- Gearing Arrangement:

-

CIt is our purpose to source a vast variety of quality items at inexpensive charges, provide the greatest services for customers content and lead to our ongoing enhancement. ycloidal

- Output Torque:

-

two.6-20000N.m

- Enter Velocity:

-

750-3000rpm

- Output Speed:

-

fourteen-280rpm

- Ratio:

-

6-51133

Provide Capability

- Source Ability:

- 50000 Established/Sets for each Year

Packaging & Delivery

- Packaging Information

- Stanard wooden case, or wooden pallet

- Port

- SHANGHAI PORT / NINGBO PORT

On-line Customization

Product Description

Swift Information:

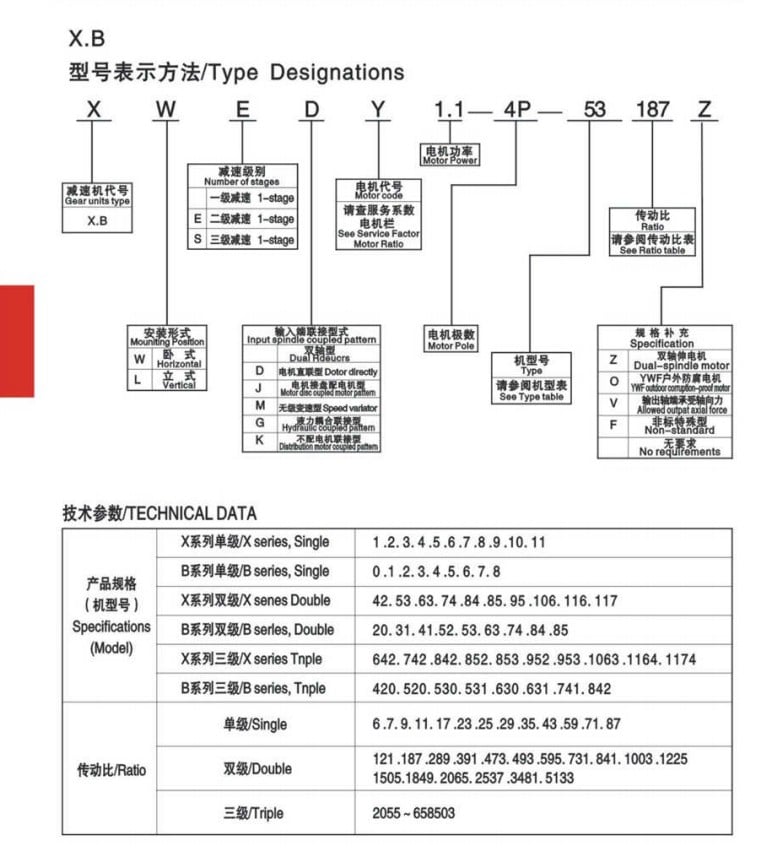

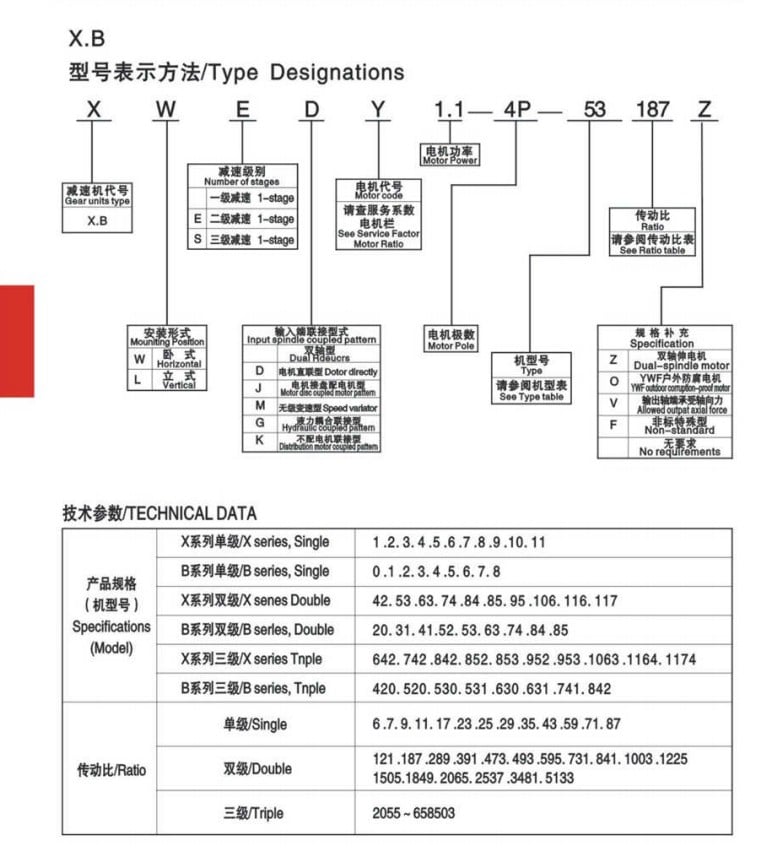

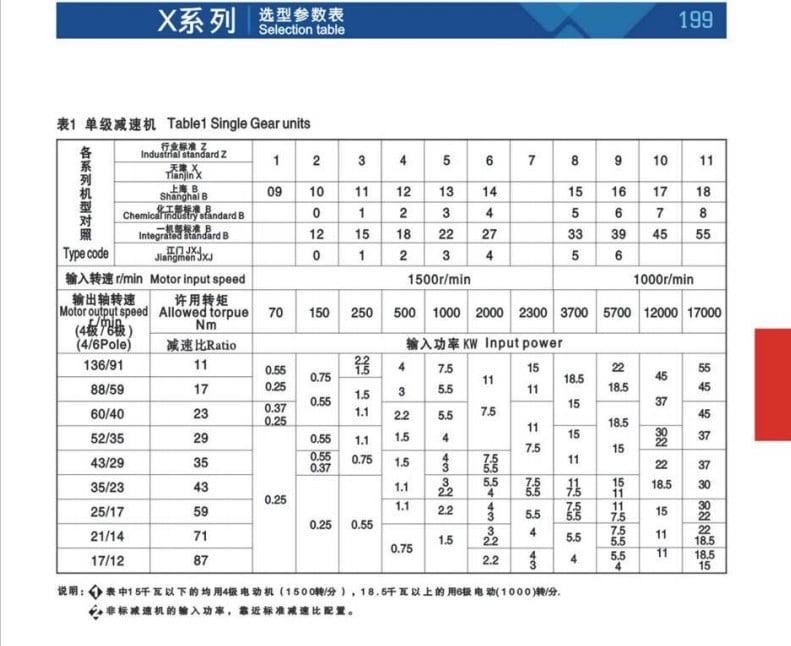

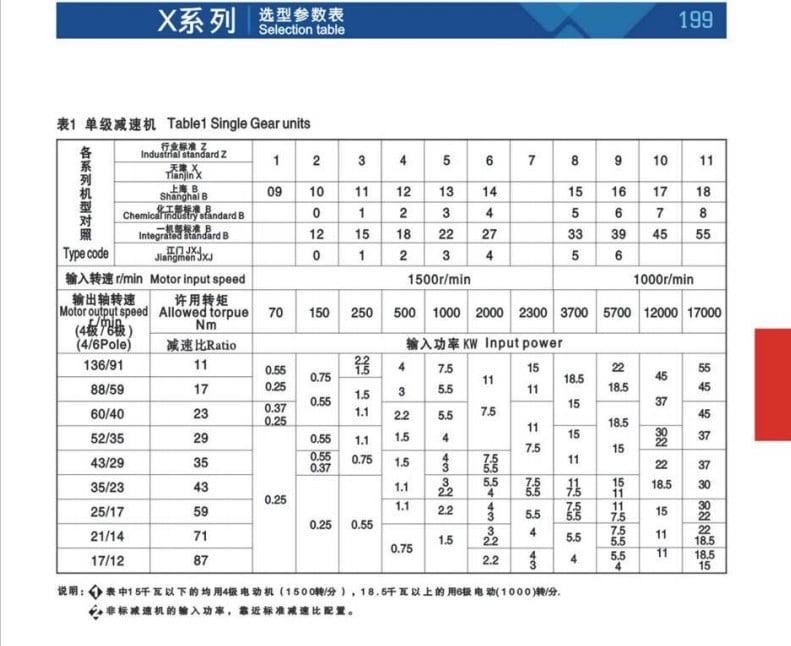

Kind: XB sequence Cycloidal Pin Wheel Pace Reducer Input Velocity: one thousand-1500rmp Output Velocity: .3-280rpm

Certification: ISO9001 CE Ex Electrical power:.09-132KW Warranty: 1Years

|

Merchandise Name |

X/B Sequence vertical kind cycloidal reducer |

|

The Gear Content |

GCR15 |

|

The case Material |

Forged Iron |

|

Coloration |

Blue,Environmentally friendly, or Customized |

|

HS Code |

84834090 |

|

Model |

XLD3 |

|

Shipping time |

10-12days |

|

Model |

TIANGOU |

Certifications

Trade Demonstrates

Packaging & Delivery

Packing Particulars : Standard carton/Pallet/Regular wood case

Delivery Information : 15-thirty doing work times upon payment

Organization Info

other series product

| Precision Planetary gearbox | Robot RV gearbox pace reducer |

| Custom made produced Non-regular Gearbox | UDL Sequence Variator |

| PYZ Collection Helical Tooth Shaft Mounted Reducer | 8000 Series Cycloidal Reducer |

| SLT Series Spiral Bevel Gearbox | SLSWL Collection Worm Screw Jack |

| SLP Series Planetary Reducer | SLH/SLB Series Large Electricity Reducer |

| NMRV Collection Worm Reducer | BKM Series Helical-hypoid Reducer |

| SLRC Collection Helical Reducer | SLSMR Sequence Shaft Mounted Reducer |

| SLXG Series Shaft Mounted Reducer | X/B Sequence Cycloidal Reducer |

| SLR/SLF/SLK/SLS Series Helical Reducer |

Relevant Items

Speak to

China manufacturer & factory supplier for china in Hargeysa Somalia supplier cycloidal gear reducer electric agitator gearbox motor for concrete mixer With high quality best price & service

ISO 9001:2015 certified company and distributor of roller chains. Kinds of roller chains include ASME/ANSI regular chains, attachment chains, corrosion resistant chains, lube-totally free chains, plastic chains, free-circulation chains, specialty chains and British normal chains. ASME/ANSI standard chains are available in massive and small pitch, double pitch and leaf styles. Roller chains are utilized in food packaging, forklift vans, oilfield drilling, motorcycles, conveyors and electricity transfer apps.Great attention has been paid on environmental protection and energy saving.

Overview

Fast Information

- Relevant Industries:

-

Producing Plant

- Pole:

-

one stage two stage a few fourstage 6 Phase

Are you seeking for a PTO water pump or PTO- pushed generator? Hundreds of PTO components from EPG suggest you can find PTO shaft areas and accessories for what ever kind of products you’re functioning with. From PTO drive shafts to defend parts, we have dozens of substitution PTO parts. We stock Eurocardan parts as effectively as Neapco parts because those are names you can believe in. Regardless of whether you require flex couplers or PTO shaft assemblies, we can aid.

- Ratio:

-

11-87

- Housing Materials:

-

Forged Iron

- Operating temperature:

-

-forty~45℃

- Application:

-

for conveyor mining, chemical market, industrial paint

- Process:

-

Carburizing, Nitriding , Grinding

- Performance:

-

94%~ninety eight%

- Mounting Situation:

-

Horizontal,Vertical,Flange

- Coloration:

-

Blue,Eco-friendly,Gray,Pink

- Sort:

-

cycloidal electric powered agitator motor gearbox gear reducer for mixing tank

Packaging & Delivery

-

Guide Time

: -

Quantity(Bags) 1 – 1 >1 Est. Time(times) ten To be negotiated

On the web Customization

Item Description

YOUR Skilled MANUFACTURE

—— Because 1995

BW(D) Series Cycloid Speed Reducer

EPG——industrial gearbox companies

cycloidal equipment reducer electric powered agitator gearbox motor for concrete mixer

Chinese electric powered motor velocity reducer is broadly employed in mining machinery, chemical business,metal metallurgy, mild industry,environmental security, paper creating, printing, lifting transport, food business and so on.

Principal Series Product: R collection helical gear reducer, K collection spiral bevel equipment reducer, NGW, P series planetary reducer, H B sequence gearbox, Z (ZDY, ZLY, ZSY, and ZFY) serial hard tooth surface cylindrical gear reducer, D (DBY and DCY) serial hard tooth surface cone equipment reducer, cycloid reducer, and many others. In the meantime, map sample processing enterprise can be carried out.

Cycloidal Pinwheel Reducer is a velocity reducing development with advance design,novel framework adopting the basic principle of planet driving and the falling-in of cycloidal pin gear. It is broadly used to the pace minimizing construction of various driving machineries ,this kind of as raise ,transportation,mine,metallurgy,petrolchemical,texitile,prention,lightindustry,pharmacy,meals,forage,foods machinery,ect.

Attribute:

- 1. Big Volecity- Minimizing Ratio:Ratio of single-phase pace-decreasing is 1/eleven-1/87 Ratio of double phase pace-decreasing is 1/112-1/5133Ratio of a few-phase speed-lowering is 1/2057-1/446571more-stages can be merged in accordance to the requirement.

-

two. High driving efficiency:Owing to adopting rolling engagement in falling-in component, the driving effectiveness can get to previously mentioned ninety%.

-

three. Small in measurement, gentle weight: with compacted framework,tiny dimension and mild bodyweight. Owing to adopting the principle of earth driving so that the enter and output shaft in the same axis which will built-in with the motor.

-

four. Long provider life: Has very good resistance to abrasion due to the fact the major driving participating components are made of bearing metal and applying rolling friction.

-

5. Stable managing: for most driving process, we adopt multi-tooth slipping-in. Then the managing will be steady with reduced sounds.

-

6. Convenient dismounting:reasonable framework and design and style.

-

seven. Strong overloading capacity,anti-compact,appropriate for regularly start off and double-facet rotation.

Specification

BWD XWD Sequence:

(you should get in touch with us for far more types & design)

Mounting Diamensions

Design selection:

Intently making use of the excellent reduction ratio.

Reduction ratio = servo motor pace / reducer output shaft speed

Torque calculation: Torque calculation is extremely crucial for the lifestyle of reducer, and pay focus to whether the optimum torque price (TP) of acceleration exceeds the optimum load torque of the reducer.

The applicable electrical power is normally the applicable electricity of the servo types on the market, the applicability of the reducer is quite large, the functioning coefficient can be maintained previously mentioned 1.2, but the option can also be primarily based on their personal requirements to determine. industrial paint cycloidal gear reducer electric agitator gearbox motor for mixing tank.

| Driven equipment | |||

| Squander water remedy | Thickeners,filter presses,flocculation apparata,aerators,raking gear,merged longitudinal and rotary rakes,pre-thickeners,screw pumps,drinking water turbines,centrifugal pumps | Dredgers | Bucket conveyors, dumping devices, carterpillar travelliAdhering to “Survival by Top quality, Improvement by Technology & Credit rating”, The company will constantly boost product efficiency to meet up with the rising client requirements in the arduous type of perform. ng gears, bucket wheel excavators as decide up, bucket wheel excavator for primitive content, cutter head, traversing gears |

| Chemical sector | Plate bending machines, extruders, dough mills, rubbers calenders, cooling drums, mixers for uniform media, agitators for media with uniform density, toasters, centrifuges | Steel operating mills | plate tilters, ingot pushers, winding equipment, cooling bed transfer frames, roller straigheners, desk constant intermittent, roller tables reversing tube mills, shears steady, casting drivers, reversing blooming mills |

| Metallic functioning mills | Reversing slabbing mills. reversing wire mills, reversing sheet mills, reversing plate mill, roll adjustment drives | Conveyors | Bucket conveyors, hauling winches, hoists, belt conveyors, good lifts, passenger lifts, apron conveyors, escalators, rail travlling gears |

| Frequency converters | Reciprocating compressors | ||

| Cranes | Slewing gears, luffing gears, travelling gears, hoisting equipment, derricking jib cranes | Cooling towers | Cooling tower fans, blowers axial and radial |

| Cane sugar production | Cane knives, cane mills | Beet sugar manufacturing | Beet cossettes macerators, extraction plants, mechanical refrigerators, juice boilers, sugar beet washing machines, sugar beet cutter |

| Paper devices | Pulper drives | Cableways | Substance ropeways, continuous ropeway |

| Cement business | Concrete mixer, breaker, rotary kilns, tube mills, separators, roll crushers | ||

Technologies

Reducer is a mechanical transmission in a lot of fields of the national financial system. The solution classes lined by the business contain all types of equipment reducer, planetary equipment reducer and worm gearbox, as well as numerous special transmission devices this sort of as pace increasing gadget, velocity management Products, such as numerous kinds of adaptable transmission gadgets, these kinds of as compound transmission. Goods and solutions in the subject of metallurgy, nonferrous metals, coal, creating supplies, ships, h2o conservancy, electrical power, development machinery and petrochemical industries.

Chinese gearbox business has a history of almost forty several years. In all fields of national financial system and countrywide protection industry, gearbox products have a broad assortment of apps. Meals light market, electric powered machinery, design machinery, metallurgy machinery, cement machinery, environmental defense machinery, digital appliances, highway building equipment, h2o conservancy equipment, chemical machinery, mining equipment, conveyor equipment, developing supplies equipment, rubber machinery, petroleum machinery and other industries have strong demand of Reducer goods. industrial paint cycloidal electric agitator motor gearbox equipment reducer for mixing tank.

Packaging & Transport

Company Info

Founded in 1995, HangZhou At any time-Power Power machinery Co.,Ltd has 22 many years of reducer manufacturing experience and trustworthiness. The company has professional engineer crew, sophisticated engineering manufacturing and experienced personnel, with located in HangZhou of ZheJiang province which has sound industrial foundation and developed transportation.

FAQ

1.QEstablished in 1986, EPG started as a manufacturer of bevel helical gearboxes, parallel shaft gearboxes, shaft-mounted gearboxes and appropriate angle gearboxes. By means of the many years, the solution variety has been widened to include new and up-to-date item strains i.e. planetary gearboxes and worm gearboxes.:Are you the manufacturing unit or investing organization?

A:We are the professional Factory with 22 a long time of knowledge.

2.Q:Can you customize according to our specifications?

A:Indeed, we can style nonstandard items in accordance to customer’s drawing and sample.

three.Q:How extended is the shipping and delivery date?

A:10-20 working days.

four.Q:Exactly where is your manufacturing facility?

A:We are in HangZhou of ZheJiang Province, you can get below by large pace teach or fly to Jinan.

Welcome to check out us!

Nrv single phase motor examples manufacturer made in China – replacement parts – in Ryazan Russian Federation Series Hollow Shaft Worm Speed Reducer Gearbox with top quality

We – EPG Group the greatest worm gearbox, couplings and gears factory in China with 5 distinct branches. For a lot more particulars: Cellular/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778083988828 /

China Prime High quality F Series Helical Gearbox

Specification

Comprehensive Pictures

| Kind: | Worm Gear Pace Reducer |

| Product: | NMRV571–150 |

| Ratio: | one:7.5,ten,15,twenty,25,30,40,fifty,sixty,eighty,one hundred |

| Coloration: | Blue/Silver Or On Customer Ask for |

| Material | Housing: Blue-Colored Forged-Iron Worm Gear-Copper-ten-3# Worm-20CrMn Ti with carburizing and quenching, surface harness is fifty six-62HRC Shaft-chromium metal-forty five# |

| Lubricant: | Artificial&Mineral |

| Bearing: | C&U Bearing |

| Seal: | NAK SKF |

| Warranty: | -30-40°C |

| ICE FLANGE | 80B5,90B5,100B5,112B5,132B5,160B5 |

| Rated electrical power: | .06KW,.12KW,.25KW,.75KW,1.5KW,3KW,5.5KW,7.5KW |

| Application | Metallurgical equipment, foodstuff equipment, phase machinery, welding machinery, street equipment, amusement devices, packaging machinery, Rubber and plastic machinery, environmental protection equipment ,engineering machinery, design equipment, equipment device business, automotive sector, logistics and transportation and so on |

Company Overview

1. AC gear motor

2. DC & BLDC gear motor

three. Worm gearbox

4. Helical gearbox

five. Coreless motor

6. PM Synchronous Motor

seven. Motor controller

8. Customized motor

If you are loo ept for motors and gearboxes, please tell us about your prerequisite. We feel we will offer a suited generate answer for you.

Firm Overview

Certificates

About Greensky Mechanical

Background: ept is a mechanical brand name of ept Electrical power Co., Ltd. With above ten years’

mechanical manufacturing ordeals, ept Electrical power constantly strictly stands on the

principle of Ideal Consumer Fulfillment.

Top quality: Material Inspection, Production Control, Finished Goods Take a look at, Pre-dellivery Inspection

MISSION: “After and eternally” is our purpose to serve buyers in the globe. Once we do

company with consumer, we will do enterprise permanently.

Marketplace: 30 distinct nations, mostly Germany, Austria, Japan, United states of america and Center-East.

Delivery: 100% on-time shipping and delivery Certain.

Services: Fast response in English, German, Japanese and Chinese languages.

OEM: Tailored orders are welcome at ept Power.

Exhibitions

FAQ

1 Q: What is actually your MOQ for Worm Gearbox?

A: 1unit is okay for diverse types.

two Q: What about your guarantee for your Worm Gearbox?

A: A single calendar year.

three Q: Do you provide OEM support with consumer-brand?

A: Sure, we could do OEM orders, but we mostly concentrate on our own model.

four Q: How about your payment phrases ?

A: TT, western union and paypal. a hundred% payment in advanced for orders considerably less $5,000. thirty% deposit and harmony ahead of shipping for orders in excess of $5,000.

five Q: How about your pac ept ?

A: Carton, Plywood case. If you want more, we can pack all products with pallet

6 Q: What details need to be given, if I purchase Worm Gearbox from you ?

A: Rated power, gearbox ratio, input velocity, mounting place. A lot more information, greater!

7 Q: How do you supply the Worm Gearbox?

A: We will evaluate and pick the most suited approaches of delivery by sea, air or categorical courier.

We hope you will enjoy cooperating with us.

/ The use of first tools manufacturer’s (OEM) portion figures or emblems , e.g. CASE® and John Deere® are for reference functions only and for indicating item use and compatibility. Our organization and the outlined substitution parts contained herein are not sponsored, accepted, or produced by the OEM. /