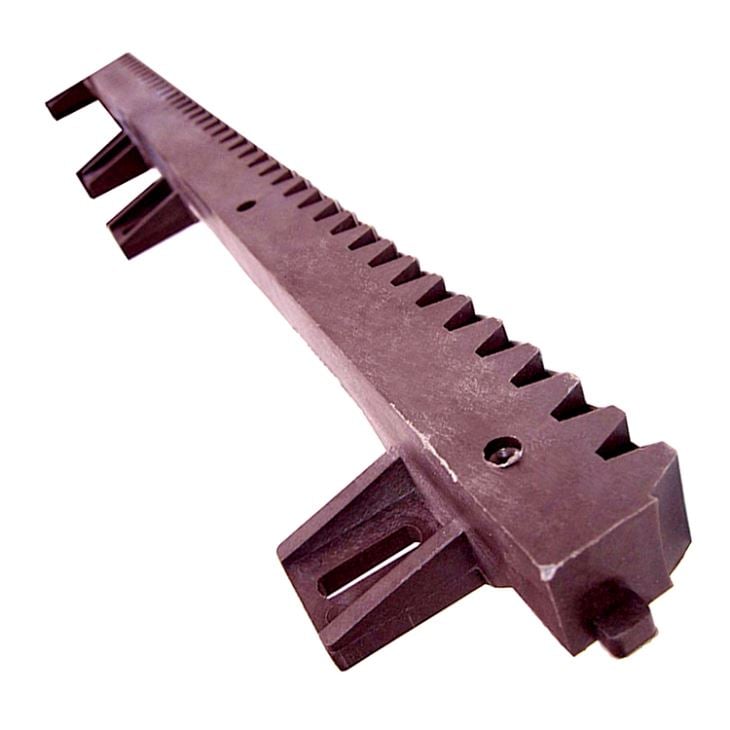

Product Description

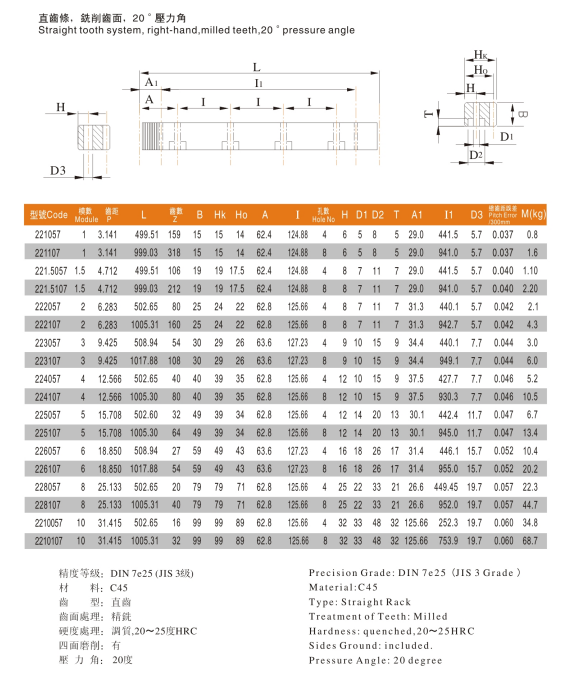

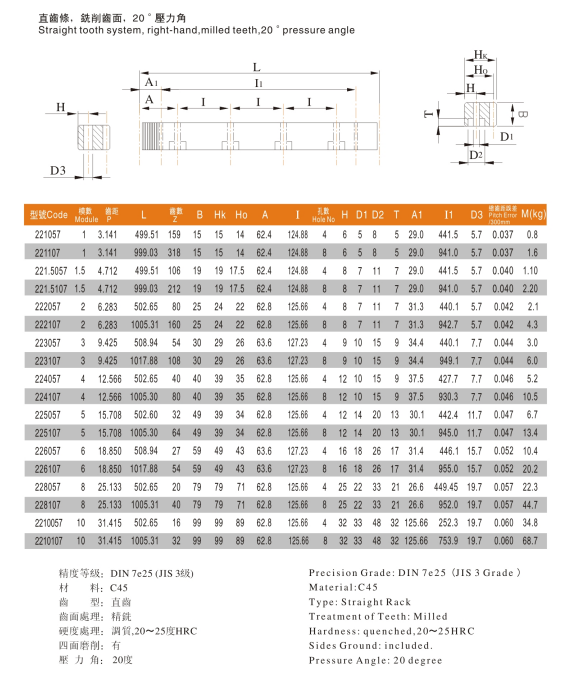

Parameter specifications

| Certification | Shipment | Quality | material | Company System Certification |

| IATF16949 | in time | high | steel | ISO9001 |

Company Profile

HangZhou Xihu (West Lake) Dis. East Port Gear Manufacturing factory is located in Zhoujia Industrial Zone, CHINAMFG Town, HangZhou, 3km away from Xihu (West Lake) Dis.qian Lake. It focuses on precision gear research, development, production and sales. The factory has obtained ISO9001: 2015 certificate, IATF16949:2016. The main export markets were North America, South America and Europe. Products can be customized and mainly includes: New Energy Motor Shaft, Oil Pump Gear, Agricultural Machinery Gear, Transmission Gear, Electric Vehicle gear, etc. We are sincerely willing to cooperate with enterprises from all over the world.

Equipment And Main Products

Certifications

FAQ

Q1:How is the quality of your product?

A:Our product has reliable quality, high wear life

Q2:Customization process/work flow?

Advisory – Material selection – 2D/3D Drawing – Quotation – Payment – Production – Quality Control – Package – Delivery

Q3: What is your terms of packing?

A:Generally, we pack our goods in wooden cases, If you have special request about packing, pls negotiate with us in advance, we can pack the goods as your request.

Q4:Price?

A:We will offer competitive price after receiving your drawing

Q5:What is your terms of payment?

A:30% T/T advanced, 70% T/T before shipping

Q6:What is your terms of delivery?

A: FOB

Q7:What drawing software does your company use?

A:CAXA

Q8:Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery

Q9:How about your delivery time?

A:Product can often be delivered within 40-90 days

Q10:Sample?

A:We offer paid sample.If you have sample requirements, please feel free to contact us at any time

Q11:What logistics packaging does your company use?

A:Express for urgent orders. UPS, FedEx, DHL, TNT, EMS.

Q12:Application range?

A:Automotive, medical, automation, agricultural, marine, etc.

Q13: How do you make our business long-term and good relationship?

A:1. We keep good quality and competitive price to ensure our customers benefit ;

2. We respect every customer as our friend and we sincerely do business and make friends with them,

no matter where they come from.

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Agricultural Machinery, Car |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Gear Position: | External Gear |

| Samples: |

US$ 50/Piece

1 Piece(Min.Order) | Order Sample customized version

|

|---|

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Can PTO shafts be adapted for use in both agricultural and industrial settings?

Yes, PTO (Power Take-Off) shafts can be adapted for use in both agricultural and industrial settings. While PTO shafts are commonly associated with agricultural machinery, they are versatile components that can be utilized in various applications beyond the agricultural sector. With appropriate modifications and considerations, PTO shafts can effectively transfer power in industrial settings as well. Here’s a detailed explanation of how PTO shafts can be adapted for both agricultural and industrial use:

1. Standard PTO Shaft Design: PTO shafts have a standardized design that allows for compatibility and interchangeability across different equipment and machinery. This standardization enables PTO shafts to be used in various applications, including both agricultural and industrial settings. The basic components of a PTO shaft, such as the universal joints, splined shafts, and protective guards, remain consistent, regardless of the specific application. This consistency allows for easy adaptation and integration into different machinery and equipment.

2. Shaft Length and Sizing: PTO shafts can be customized in terms of length and sizing to suit specific requirements in both agricultural and industrial settings. The length of the shaft can be adjusted to accommodate different distances between the power source and the driven machinery. This flexibility allows for optimal power transmission and ensures compatibility with various equipment setups. Similarly, the sizing of the PTO shaft, including the diameter and splined shaft specifications, can be tailored to meet the torque and power requirements of different applications, whether in agriculture or industry.

3. Power Requirements: PTO shafts are designed to transfer power from a power source to driven machinery. In agricultural settings, the power source is typically a tractor or other agricultural vehicles, while in industrial settings, it can be an engine, motor, or power unit specific to the industry. PTO shafts can be adapted to handle different power requirements by considering factors such as torque capacity, rotational speed, and the specific demands of the machinery or equipment being driven. By selecting the appropriate PTO shaft based on the power requirements, the shaft can effectively transfer power in both agricultural and industrial applications.

4. Safety Considerations: Safety is a critical aspect of PTO shaft design and usage, regardless of the application. PTO shafts incorporate safety features such as protective guards and shields to prevent accidental contact with rotating components. These safety measures are essential in agricultural and industrial settings to minimize the risk of entanglement, injury, or damage. Adapting PTO shafts for industrial use may require additional safety considerations based on the specific hazards present in industrial environments. However, the core safety principles and features of PTO shafts can be applied and adapted to ensure safe operation in both settings.

5. Specialized Attachments: PTO shafts can be equipped with specialized attachments or adapters to accommodate different driven machinery or equipment. In agricultural settings, PTO shafts commonly connect to implements such as mowers, balers, or sprayers. In industrial settings, PTO shafts may be adapted to connect to various industrial machinery, including pumps, generators, compressors, or conveyors. These specialized attachments ensure compatibility and efficient power transfer between the PTO shaft and the driven equipment, allowing for seamless integration in both agricultural and industrial applications.

6. Environmental Considerations: PTO shafts can be adapted to address specific environmental conditions in both agricultural and industrial settings. For example, in agricultural applications, PTO shafts may need to withstand exposure to dirt, dust, moisture, and varying weather conditions. Industrial settings may have their unique environmental challenges, such as exposure to chemicals, high temperatures, or abrasive materials. By selecting PTO shaft materials, protective coatings, and seals suitable for the specific environment, the shafts can be adapted to ensure reliable and durable performance in various settings.

7. Compliance with Standards: PTO shafts, whether used in agricultural or industrial settings, need to comply with relevant safety standards and regulations. Manufacturers adhere to guidelines and requirements set by organizations such as the American Society of Agricultural and Biological Engineers (ASABE) or other regional safety authorities. Compliance ensures that PTO shafts meet safety criteria and performance standards applicable to both agricultural and industrial environments. Users can rely on standardized PTO shafts that have undergone testing and certification, offering assurance regarding their reliability and safety.

By considering the factors mentioned above, PTO shafts can be adapted to effectively transfer power in both agricultural and industrial settings. The versatile nature of PTO shafts, coupled with customization options, safety considerations, specialized attachments, and compliance with standards, allows for their successful integration into a wide range of machinery and equipment across various industries.

How do PTO shafts handle variations in load and torque during operation?

PTO (Power Take-Off) shafts are designed to handle variations in load and torque during operation by employing specific mechanisms and features that ensure efficient power transfer and protection against overload conditions. Here’s a detailed explanation of how PTO shafts handle variations in load and torque:

1. Mechanical Design: PTO shafts are engineered with robust mechanical design principles that enable them to handle variations in load and torque. They are typically constructed using high-strength materials such as steel, which provides durability and resistance to bending or twisting forces. The shaft’s diameter, wall thickness, and overall dimensions are carefully calculated to withstand the expected torque levels and load variations. The mechanical design of the PTO shaft ensures that it can transmit power reliably and accommodate the dynamic forces encountered during operation.

2. Universal Joints: Universal joints are a key component of PTO shafts that allow for flexibility and compensation of misalignment between the power source and driven machinery. These joints can accommodate variations in angular alignment, which may occur due to changes in load or movement of the machinery. Universal joints consist of a cross-shaped yoke with needle bearings that allow for smooth rotation and transfer of torque, even when the shafts are not perfectly aligned. The design of universal joints enables PTO shafts to handle variations in load and torque while maintaining consistent power transmission.

3. Slip Clutches: Slip clutches are often incorporated into PTO shafts to provide overload protection. These clutches allow the PTO shaft to slip or disengage momentarily when excessive torque or resistance is encountered. Slip clutches typically consist of friction plates that can be adjusted to a specific torque setting. When the torque surpasses the predetermined limit, the clutch slips, preventing damage to the PTO shaft and connected equipment. Slip clutches are particularly useful when sudden changes in load or torque occur, providing a safety mechanism to protect the PTO shaft and associated machinery.

4. Torque Limiters: Torque limiters are another protective feature found in some PTO shafts. These devices are designed to automatically disengage the power transmission when a predetermined torque threshold is exceeded. Torque limiters can be mechanical, such as shear pin couplings or friction clutches, or electronic, utilizing sensors and control systems. When the torque exceeds the set limit, the torque limiter disengages, preventing further power transfer and protecting the PTO shaft from overload conditions. Torque limiters are effective in handling sudden spikes in torque and safeguarding the PTO shaft and associated equipment.

5. Maintenance and Inspection: Regular maintenance and inspection of PTO shafts are essential to ensure their proper functioning and ability to handle variations in load and torque. Routine maintenance includes lubrication of universal joints, inspection of shaft integrity, and tightening of fasteners. Regular inspections allow for early detection of wear, misalignment, or other issues that may affect the PTO shaft’s performance. By addressing maintenance and inspection requirements, operators can identify and address any concerns that may arise due to variations in load and torque, ensuring the continued safe and efficient operation of the PTO shaft.

6. Operator Awareness and Control: Operators play a crucial role in managing variations in load and torque during PTO shaft operation. They should be aware of the machinery’s operational limits, including the recommended torque ratings and load capacities of the PTO shaft. Proper training and understanding of the equipment’s capabilities enable operators to make informed decisions and adjust the operation when encountering significant load or torque changes. Operators should also be vigilant in monitoring the equipment’s performance, watching for any signs of excessive vibration, noise, or other indications of potential issues related to load and torque variations.

By incorporating robust mechanical design, utilizing universal joints, slip clutches, torque limiters, and implementing proper maintenance practices, PTO shafts are equipped to handle variations in load and torque during operation. These features ensure reliable power transmission, protect against overload conditions, and contribute to the safe and efficient functioning of the PTO shaft and the machinery it drives.

How do PTO shafts contribute to transferring power from tractors to implements?

PTO shafts (Power Take-Off shafts) play a critical role in transferring power from tractors to implements in agricultural and industrial settings. They provide a reliable and efficient means of power transmission, enabling tractors to drive various implements and perform a wide range of tasks. Here’s a detailed explanation of how PTO shafts contribute to transferring power from tractors to implements:

Power Source: Tractors are equipped with powerful engines designed to generate substantial amounts of mechanical power. This power is harnessed to drive the tractor’s wheels and operate hydraulic systems, as well as to provide power for the attachment of implements through the PTO shaft. The PTO shaft typically connects to the rear or side of the tractor, where the power take-off mechanism is located. The power take-off derives power directly from the tractor’s engine or transmission, allowing for efficient power transfer to the PTO shaft.

PTO Shaft Design: PTO shafts are designed as driveline components that transmit rotational power and torque from the tractor’s power take-off to the implement. They consist of a hollow metal tube with universal joints at each end. The universal joints accommodate angular misalignments and allow the PTO shaft to transmit power even when the tractor and implement are not perfectly aligned. The PTO shaft is also equipped with a safety shield or guard to prevent accidental contact with the rotating shaft, ensuring operator safety during operation.

PTO Engagement: To transfer power from the tractor to the implement, the PTO shaft needs to be engaged. Tractors are equipped with a PTO clutch mechanism that allows operators to engage or disengage the PTO shaft as needed. When the PTO clutch is engaged, power flows from the tractor’s engine through the power take-off mechanism and into the PTO shaft. This rotational power is then transmitted through the PTO shaft to the implement, driving its working components.

Rotational Power Transmission: The rotational power generated by the tractor’s engine is transferred to the PTO shaft through the power take-off mechanism. The PTO shaft, being directly connected to the power take-off, rotates at the same speed as the engine. This rotational power is then transmitted from the PTO shaft to the implement’s driveline or gearbox. The implement’s driveline, in turn, distributes the power to the implement’s working components, such as blades, augers, or pumps, enabling them to carry out their respective functions.

Matching Speed and Power: PTO shafts are designed to match the rotational speed and power requirements of various implements. Tractors often feature multiple speed settings for the PTO, allowing operators to select the appropriate speed for the specific implement being used. Different implements may require different rotational speeds to operate optimally, and the PTO shaft allows for easy adjustment to match those requirements. Additionally, the power generated by the tractor’s engine is transmitted through the PTO shaft, providing the necessary torque to drive the implement’s working components effectively.

Versatility and Efficiency: PTO shafts offer significant versatility and efficiency in agricultural and industrial operations. They allow tractors to power a wide range of implements, including mowers, balers, tillers, sprayers, and grain augers, among others. By connecting implements directly to the tractor’s power source, operators can quickly switch between tasks without the need for separate power generators or engines. This versatility and efficiency streamline workflow, reduce costs, and increase overall productivity in agricultural and industrial settings.

Safety Considerations: While PTO shafts are essential for power transmission, they can pose safety risks if mishandled. The rotating shaft and universal joints can cause severe injuries if operators come into contact with them while in operation. That’s why PTO shafts are equipped with safety shields or guards to prevent accidental contact. Operators should always ensure that the safety shields are in place and secure before engaging the PTO shaft. Proper training, adherence to safety guidelines, and regular maintenance of PTO shafts and associated safety features are crucial to ensuring safe operation.

In summary, PTO shafts are vital components that enable the transfer of power from tractors to implements in agricultural and industrial applications. They provide a reliable and efficient means of power transmission, allowing tractors to drive various implements and perform a wide range of tasks. By engaging the PTO clutch and transmitting rotational power through the PTO shaft, tractors power the working components of implements, providing versatility, efficiency, and productivity in agricultural and industrial operations.

editor by CX 2023-12-25

Mc made in China – replacement parts – in Al-Raqqa Syrian Arab Republic Nylon Gear Rack with High Quality with ce certificate top quality low price

We – EPG Team the bigge EPT Chain and agricultural gearbox manufacturing facility in China with 5 diverse branches. For much more details: Cell/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778 0571 88828

Item Description

MC nylon gear rack with high good quality

Rewards:

one. Very good Tensile energy

2. Higher affect and notching effect strength

3. High heat deflection temperature

four. Large toughness and stiffness

five. Great glide and limp house people

six. Good chemical balance again EPT natural and organic solvents and fuels

7. Resistant to thermal growing older (relevant temperature among -50°C and 110°C

eight. Size alternation by humidity absorption mu EPT be deemed

Application:

one. Nylon PA6 Goods that made by HangZhou EPT Plastics Industries (Team) Company is commonly substituted for dress in areas of mechanical tools, or employed as quick-put on elements of tools as an alternative of copper and alloy

2. Shaft sleeve, bearing bush, lining, lining plate, gear

three. Worm equipment, roller copper information rail, piston ring, seal ring, slide block

four. Spheric bowl, impeller, blade, cam, nut, valve plate,

five. Pipe, stuffing box, rack, belt pulley, pump rotor, and so forth.

Primary Qualities of PA66 nylon equipment rack

| Property | Item No. | Device | MC Nylon (Natural) | Oil Nylon+Carbon (Black) | Oil Nylon (Inexperienced) | MC901 (Blue) | MC Nylon+MSO2 (Light black) | |

| Mechanical Homes | 1 | Density | g/cm3 | 1.15 | 1.15 | one.one hundred thirty five | 1.15 | one.sixteen |

| two | Water absorption (23ºC in air) | % | one.8-2. | 1.8-2. | 2 | 2.three | two.4 | |

| 3 | Tensile strength | MPa | 89 | 75.3 | 70 | eighty one | 78 | |

| 4 | Tensile strain at split | % | 29 | 22.7 | twenty five | 35 | twenty five | |

| 5 | Compressive pressure(at 2%nominal strain) | MPa | fifty one | 51 | 43 | 47 | forty nine | |

| 6 | Charpy effect energy (unnotched) | KJ/m2 | No break | No split | ≥50 | No BK | No break | |

| 7 | Charpy affect energy (notched) | KJ/m2 | ≥5.seven | ≥6.4 | 4 | 3.5 | three.5 | |

| eight | Tensile modulus of elasticity | MPa | 3190 | 3130 | 3000 | 3200 | 3300 | |

| 9 | Ball indentation hardness | N/mm2 | 164 | 150 | one hundred forty five | a hundred and sixty | one hundred sixty | |

| ten | Rockwell hardness | – | M88 | M87 | M82 | M85 | M84 | |

Our Service:

1. Rich industry experience since 1988.

two. Wide arrange product line, including plastics sheet/rod/components/equipment: MC NYLON, OIL NYLON, POM, UHMW-PE, PU, PETP, PC, PTFE, PVDF, PPS, PEEK, PAI, PI, PBI ect.

3. Manufacture, design and processing service as per your demand.

Product technology:

CNC machine,Extrusion,Injection,ect.

Processing Equipment :

CNC machining center,CNC lathes,Milling,Injection Molding Machine,Extruder,Moulding press

Packaging &Delivery:

Packing in plastics bags,wooden case,pallet,container,ect.

Certification:

Certification:ISO,SGS,Fda,RoHS,Test report,ect.

FAQ:

one.A: What’s the size of plastics sheet?

B:Nylon sheet:Thickness*Width*Length:20-a hundred*a thousand*2000mm

UHMW-PE sheet:Thickness*Width*Duration:20-100*a thousand*2000mm 20-a hundred*1250*3130mm 20-a hundred*1250*4250mm

POM sheet:Width*Length:1000*2000mm

two. A:Can we purchase a small part of plastics sheet?

B: Yes,you can, if we have the size you require in stock.

three. A:What color of plastics sheet?

B: Nylon sheet: Natural,black,blue,or according to client’s requiremnet.

UHMW-PE sheet: White,black,green ,bule,yellow,or according to client’s requirement.

White,black

four. A:Can you manufacture the plastics products as per drawing?

B: Yes,we can.

5.A: What the precision of plastic products according to drawing?

B: Different machine with different precision,it usually around 0.05-.1mm

six.A: What the technologies in producing plastics parts?

B: Different products with different technologies,such as CNC machine,Extrusion,Injection

7: A:What kinds of processing machine do you have?

B: CNC machining center,CNC lathes,Milling,Injection Molding Machine,Extruder,Moulding press

The use of unique tools manufacturer’s (OEM) component figures or trademarks , e.g. CASE® and John Deere® are for reference reasons only and for indicating product use and compatibility. Our organization and the shown alternative areas contained herein are not sponsored, accepted, or made by the OEM.

China manufacturer & factory supplier for China in Khabarovsk Russian Federation manufacturer Hot sale China manufacturer produce high precision CNC gear and rack With high quality best price & service

corrosion- and put on-resistant coiled tubing injector roller chain assemblies for the oil and gas industries. Available in single and double pitch generate chain sorts with numerous measurements and electrical power ranking. Features contain zinc-nickel and non-hexavalent chromate protective exterior coating, electrochemically bonded, and interference match cover plates. we have received the believe in of consumers worldwide. a specialized supplier of a full assortment of chains, sprockets, gears, gear racks, V-belts, couplings and reducers, pto shaft, agricultural gearboxes….

Overview

Quick Information

- Relevant Industries:

-

Creating Material Stores, Manufacturing Plant, Equipment Fix Stores, Meals & Beverage Factory, Farms, Power & Mining

- Other Country:

-

TianJin,China

- Solution title:

-

Straight Equipment Rack

- Colour:

-

Mother nature Colour

- Software:

-

Market Equipment

- Precision grade:

-

Din7

- Area treatment:

-

Grinding

- Hardness:

-

twenty-twenty five Diploma HRC

- Standard:

-

common

- Stress:

-

twenty Diploma

- Sides ground:

-

Integrated

Supply Potential

- Supply Capacity:

- ten thousand Piece/Parts for every Month

Packaging & Shipping

- Packaging Specifics

- wood/ carton

Our products is well-liked exported to the United States, Germany, Australia, Russia, Spain, Hungary, Zimbabwe, Ukraine, Nigeria, Peru, Brazil, Middle and South The us, Thailand, Pakistan, Indonesia, a lot more than 60 nations around the world and regions.

- Port

- TIANJIN PORT

-

Guide Time

: -

Quantity(Baggage) SFI M100 PTO AdapterAs a precautionary evaluate, it is a very good notion to acquire a PTO adapter to make sure compatibility with your distinct tractor product.

one – two 3 – one hundred >100 Est. Time(times) three ten To be negotiated

Online Customization

You gain from our complete expertise of the interaction in between all the components in the generate train. For exact sizing and design of the entire drive practice, we use our innovative EPG ® 5 design application.

EPG offer you widest assortment of gearbox and velocity reducers, conveyor chains and transmission parts like equipment, sprocket, racks, pulley, shaves and taper bushes and so on for various programs

Specification

|

Solution name |

Equipment rack |

||||||

|

Type |

Helical equipment rack,spur equipment rack |

||||||

|

Material |

C45,steel,carbon metal,stainless steel,plastic,nylon,POM,ect |

||||||

|

Precision |

DIN6,DIN7,DIN8,DIN9,DIN10 |

||||||

|

Model |

M1,M1.twenty five,M1.5,M2.M3,M4,M5,M6,M8,M10 |

||||||

|

Procedure |

Equipment Hobbing, Gear Milling, Equipment Shaping, Equipment Broaching, |

||||||

|

Heat treatment method |

Quenching & Tempering, Carburizing & Quenching, High-frequency Hardening, Carbonitriding |

||||||

|

Area treatment method |

Blacking, Sprucing, Anodization, Chrome Plating, Zinc Plating, Nickel Plating. |

||||||

Apply to equipment

|

merchandise title |

straight equipment rack |

|

brand name |

EPG – The greatest transmission components manufacuturer in China |

|

region of location |

TianJin,China |

|

coloration |

organic |

|

processing |

grinding |

|

Din precision |

DIN6 |

Catalog

Installation

Packing & Shipping

Principal item

Software

Company profile

HangZhou EPG – The largest transmission elements manufacuturer in China Electrical Tools Co.,Ltd was established in HangZhou in 2008 and is a expert maker and exporter that is involved with the design and style, improvement and production.With comprehensive requirments, we can also develop your particular developed item. Our item variety contains all varieties of helical gear, spur equipment, bevel equipment, equipment rack, worm equipment, sprockets,chains, bearings.Keeping in head that excellent support is the essential to cooperating with clientele, we attempt to satisfy substantial top quality specifications, offer aggressive costs and ensure prompt shipping and delivery.

Payment

CNC made in China – replacement parts – in Comilla Bangladesh Machining Circular Gear Rack with ce certificate top quality low price

We – EPG Group the bigge EPT Chain and agricultural gearbox manufacturing facility in China with 5 distinct branches. For much more details: Mobile/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778 0571 88828

Material&colon Gentle steel&comma ca EPT steel&comma ca EPT iron&comma cast metal&comma stainless steel&comma alloy metal&comma Plastic&comma POM&comma aluminium alloy&comma zn alloy&comma bronze&comma brass&comma chrome&comma 40Cr&comma 20CrMnTi&comma Metal 1571&comma Steel 1045

Modulus&colon M1&comma M1&period5&comma M2&comma M2&period5&comma M3&comma M4&comma M5&comma M6&comma M7&comma M8&comma M10&time period M12

We also can make according to clients’ drawings or styles

Aggressive cost & primary high quality & be EPT support & well timed shipment

Supply time&colon 3 months&time period

The use of original equipment manufacturer’s (OEM) component numbers or logos , e.g. CASE® and John Deere® are for reference purposes only and for indicating product use and compatibility. Our company and the outlined substitute areas contained herein are not sponsored, accredited, or created by the OEM.

Best China manufacturer & factory Customize in Van Turkey OEM Factory Price Helical Gear Rack and Pinion With high quality best price

Meanwhile, our products are manufactured according to high quality standards, and complying with the international advanced standard criteria.

Overview

Quick Details

- Applicable Industries:

-

Manufacturing Plant

- Place of Origin:Zhejiang, China

- Competitive:

-

Price and quality

- Weight:

-

0.2g – 1000g

- Normal material:

-

POM, ABS, Nylon, PP, PC, plastic etc

- MOQ:

-

1 pc

- Service:

-

Reply in 12 hours at any time

- Color:

-

White, Black, Blue, Green etc.

- Technic:

-

Injection

Supply Ability

- Supply Ability:

- 500000 Piece/Pieces per Month

Packaging & Delivery

- Packaging Details

- carton box

- Port

- Ningbo, Shanghai, Qingdao or as request

-

Lead Time

: -

Quantity(Bags) 1 – 10000 10001 – 100000 100001 – 500000 >500000 Est. Time(days) 10 20 45 To be negotiated

Online Customization

If the gear reducer had to be painted, the detents must be covered to prevent them from drying and losing their seal. The machine work of the fittings set up in the output shafts need an ISO H7 or h6 margin for the hollow shaft.

Most commonly, it is a splined drive shaft installed on a tractor or truck allowing implements with mating fittings to be powered directly by the engine.

Most commonly, it is a splined drive shaft installed on a tractor or truck allowing implements with mating fittings to be powered directly by the engine.

Product Description

|

Facilities |

Machining center; |

||||||

|

Mateiral |

ABS, PC, PP, PS, POM, PMMA,PBT,PVC,PA6,PA66,PA66+30%GF, |

||||||

|

Technic |

Machining for small quantity, and injection for large quantity. |

||||||

|

Color |

Color painting,Texture,Silk-printing,Vacuum coating,rubber coating, etc. |

||||||

|

More material |

Steel, Stainless steel, Copper, Aluminium, Aluminium Alloy etc. |

||||||

1. Delivery time: 7-10 days for small order;

12-20 days for big order. (Never delayed till now)

Can be discussed for more urgent order.

2. Response time: usually in 1 hour and in 12 hours even in our holidays.

3. Process feedback: Photos or vedios will be sent for 2-3 times to inform you the producing situation.

4. Test report: The test report can be offered as request.

5. Trade terms: FOB, CFR, CIF, FCA, CPT, CIP, DDU, DDP etc.

Detailed Images

Related product

Company Profie

SPECIALIST IN MAKING ALL KINDS OF MECHANICAL TRANSMISSION AND HYDRAULIC TROur factory has obtained the certificate of China’s Farm Machinery Products Quality Authentication promulgated by the Farm Machinery Products Quality Authentication Centre of China. ANSMISSION LIKE: PLANETARY GEARBOXES, WORM REDUCERS, IN-LINE HELICAL GEAR SPEED REDUCERS, ARALLEL SHAFT HELICAL GEAR REDUCERS, HELICAL BEVEL REDUCERS, HELICAL WORM GEAR REDUCERS, AGRICULTURAL GEARBOXES, TRACTOR GEARBOXES, AUTO GEARBOXES, PTO DRIVE SHAFTS, SPECIAL REDUCER & RELATED GEAR COMPONENTS AND OTHER RELATED PRODUCTS, SPROCKETS, HYDRAULIC SYSTEM, VACUUM PUMPS, FLUID COUPLING, GEAR RACKS, CHAINS, TIMING PULLEYS, UDL SPEED VARIATORS, V PULLEYS, HYDRAULIC CYLINDER, GEAR PUMPS, SCREW AIR COMPRESSORS, SHAFT COLLARS LOW BACKLASH WORM REDUCERS AND SO ON. FURTHERMORE, WE CAN PRODUCE CUSTOMIZED VARIATORS, GEARED MOTORS, ELECTRIC MOTORS AND OTHER HYDRAULIC PRODUCTS

ACCORDING TO CUSTOMERS’ DRAWINGS.

Certifications

FAQ

Q: Are you trading company or manufacturer ?

A: Our group consists in 3 factories and 2 abroad sales corporations.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: How long is your delivery time ? What is your terms of payment ?

A: Generally it is 40-45 days. The time may vary depending on the product and the level of customization. For standard products, the payment is: 30% T/T in advance ,balance before shippment.

Q: What is the exact MOQ or price for your product ?

A: As an OEM company, we can provide and adapt our products to a wide range of needs.Thus, MOQ and price may greatly vary with size, material and further specifications; For instance, costly products or standard products will usually have a lower MOQ. Please contact us with all relevant details to get the most accurate quotation.

If you have another question, please feel free to contact us.

Packing & Delivery

Why Choose Us

Also I would like to take this opportunity to give a brief introduction of our Ever-Power company:

Our company is a famous manufacturer of agriculture gearbox,worm reduce gearbox, PTO shafts, Sprockets ,rollar chains, bevel gear, pulleys and racks in china.

We have exported many products to our customers all over the world, we have long-time experience and strong technology support.

Some of our customer :

Italy: GB GEABOX, SATI, CHIARAVALLI, AMA, Brevini

Germany: SILOKING ,GKN ,KTS

France: Itfran, Sedies, Kuhn

Brazil: AEMCO ,STU

USA: John Deere , BLOUNT, Weasler, Agco, Omni Gear, WOODS

Canada: JAY-LOR , CANIMEX ,RingBall

……

-> Our Company with over twelve year’s history and 1000 workers and 20 sales.

-> With over 100 Million USD sales in 2017

-> With advance machinery equipments

-> With large work capacity and high quality control, ISO certified.

……

you also can check our website to know for more details, if you need our products catalogue, please contact with us.

For more detail, please contact us.